Medical Plastic Injection Moulding Market Growth and Expectations

The global Medical Plastic Injection Moulding market is expected to experience phenomenal growth in the coming years, thanks to new developments and technology, increasing demand for medical products at affordable prices and high efficiency.

Medical Plastic Injection Moulding market forecasts

The global market for medical plastic injection moulding is expected to grow at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2029, from USD 34,780 million in 2022 to USD 51,950 million in 2029, according to the 2024 New Survey.

It is expected that the worldwide medical device market will reach a value of USD 603 billion in 2023 and expand at a compound annual growth rate (CAGR) of 5% over the following 6 years. The ageing population’s increasing health demands, the rise in infectious and chronic illness rates, and the development of developing markets have all contributed to a 10% increase in global healthcare spending in recent years. The healthcare sector is heavily reliant on the medical equipment business. A number of reasons, including the expanding elderly population, rising healthcare costs, growing demand for sophisticated healthcare services internationally, technological improvements, and increased awareness of early illness detection and treatment, are driving this market.

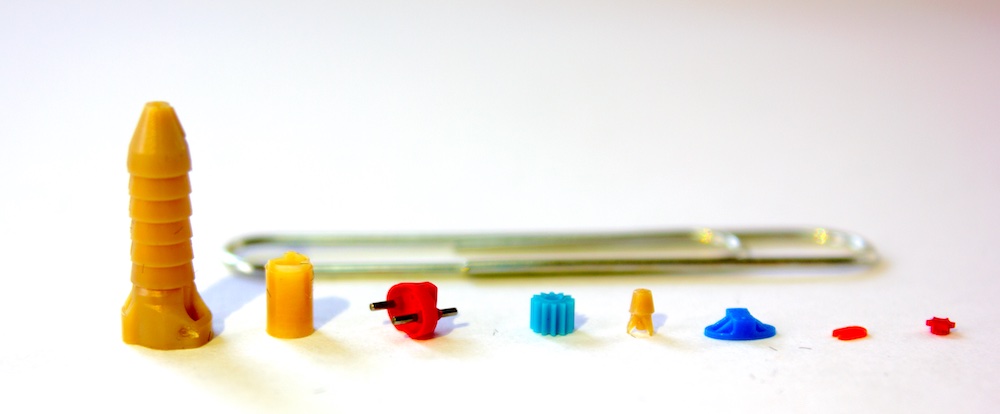

Due to their inherent resistance to poisons and impurities, medical-grade injection-moulded goods are becoming more and more in demand worldwide. Medical devices with unique geometrics that need extremely precise components may be manufactured using medical injection moulding, which works well for both basic and sophisticated medical devices. Especially, micro injection moulding can allow for medical components with micro and nano features, which can be significantly useful for various medical applications. Thus, the growing use of medical injection moulding to produce a wide range of medical devices is anticipated to drive the industry’s expansion throughout the course of the projection period.

Photo: Medical micro injection moulded parts manufactured by Micro Systems

Medical Plastic Injection Moulding market by runner systems

Based on a recent research, in 2020, hot runner systems generated over 57.90% of worldwide sales, dominating the sector. Their expansion may be ascribed to the several benefits they provide, including shortened cycle times, lower pressure needs to force the molten mixture into the mould cavity and higher production quantities. Consequently, there is a growing need for hot runner systems, and throughout the course of the forecast period, the market is anticipated to expand at a compound annual growth rate (CAGR) that is steady.

Conversely, cold runner systems are preferred due to their low cost and ease of maintenance, which makes them suitable for a variety of polymers. They also provide quick modifications or upgrades to gate positions, are flexible in terms of design possibilities, and are capable of handling a variety of engineered thermoplastics, at a affordable investment.

Medical Plastic Injection Moulding market by regions

Based on a recent research, it is anticipated that the medical plastic injection moulding market would see significant expansion in many areas, such as North America, Europe, Asia Pacific (APAC), the United States and China. Because of its sophisticated healthcare system and rising medical device demand, North America is expected to lead the market. Due to the region’s expanding population and rising healthcare costs, APAC is predicted to see tremendous growth. The European area is also expected to increase significantly as well because of the growing elderly population and improvements in medical technology. According to estimates, the following market shares belong to each region: North America (40%), APAC (35%), Europe (15%), the USA (5%), and China (5%).

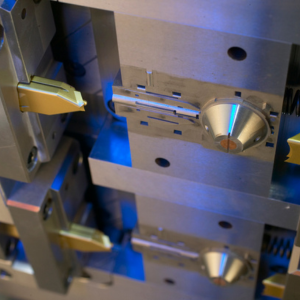

Photo: Dedicated ISO Class 7 clean room moulding areas for medical purposes at Micro Systems

Why choose Micro Systems for your Medical Plastic Injection Moulding project?

For the last 20 years, Micro Systems has been specialising in the design, manufacture and validation of ultra precision injection moulds for the medical, pharmaceutical, diagnostics and ophthalmic markets. With our groundbreaking techniques and experienced teams in the UK and Singapore, Micro Systems has made significant progress in moving from micro to nano manufacturing.

Micro Systems has dedicated ISO Class 7 clean room moulding areas, with the latest generation of micro moulding machines and inspection equipment, in prime locations in the UK and Singapore, servicing businesses across continents. Micro Systems is also able to provide mould testing and other production options, including ‘two material’ moulding with our Optimold facility (ISO 13485) in the UK.

Micro Systems always works closely with valued customers to turn their vision into reality.

Contact us today to discuss your Medical Plastic Injection Moulding projects!