Essential tips to choose the right injection mould tooling supplier

In the plastic injection moulding industry, choosing the right mould tooling supplier is a vital step for any moulding project, as the success and quality of the final products will be greatly impacted by the skill and expertise of the chosen injection mould toolmaker

So, with thousands of available injection mould tooling suppliers available on the market, how to choose the right supplier that will ensure the best outcomes for your projects?

Design capabilities and In-house tool manufacture

Choosing an injection moulding supplier with in-house tool making facilities and design expertise can be advantageous. This indicates that the entire injection moulding process—from tool creation to design—takes place in one location, which then removes potential supply chain delays, facilitates team communication at every stage of the process, and promotes effective project workflow.

Micro Systems has experienced teams of in-house mould tooling designers and technicians, with an on-site injection moulding supplier Optimold, hence, we can provide unique turnkey manufacturing solutions for various plastic injection moulding projects, from prototyping to mass production ones.

Specialist industry knowledge

In order to create high-quality mould tools that satisfy customers’ unique needs, a deep understanding of the intricacies of the injection moulding production process as well as tool design, changes, trialling, and material performance is necessary. Customers should seek out suppliers who have a strong track record of completing profitable projects with reliable partners, especially ones who fit the particular requirements of their sector.

In addition to offering invaluable insights into distinctive design elements, injection moulding experts may offer advice on how to optimise moulds for improved performance and economy in your sector. This specialised knowledge gives customers a competitive edge over rivals by improving the manufacturing process and bolstering the overall success of your moulded products.

Photo: The team of mould tooling and moulding experts at Micro Systems

Certified quality management system

A Quality Management System (QMS) is a structured framework that records the steps, protocols, and accountabilities necessary to accomplish project objectives, such as injection moulding or tool fabrication. For example, ISO 9001 is a globally renowned quality management system that is founded on seven key quality management concepts, such as a strong customer focus, top management engagement, and a commitment to continuous development.

In the production of injection moulding tools, especially for tools used in the medical industry, quality is unavoidable. In order to ensure the dependability and longevity of their moulds, customers must collaborate with a toolmaker who not only complies with the strictest industry requirements but also has strict quality control procedures in place. Micro Systems is ISO 9001 and ISO 13485 accredited for many years, with strict quality management procedures to ensure the highest requirements are met.

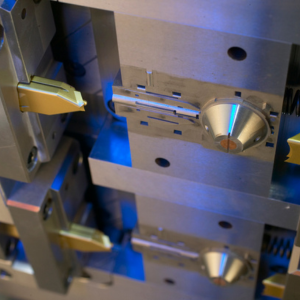

State-of-the-art technologies

Modern machinery is needed for modern plastic injection mould tooling and moulding. To develop and manufacture moulds that meet the highest requirements of quality and precision, state-of-the-art equipment and software are essential.

At Micro Systems, we use advanced equipment and a variety of complex procedures, from design software, tooling machines and metrology, to produce one-of-a-kind designs and finishes that ensure customers’ highest satisfaction.

Photo: Medical-class Micro injection moulding facilities at Micro Systems

Sustainability and Corporate Social Responsibility

It’s more crucial than ever for businesses and brands to take the environment into account these days. Collaborating with businesses that track their environmental impact is among the simplest methods to minimise your own.

Sustainability and Corporate Social Responsibility are becoming more and more important at Micro Systems, as we understand our responsibility in supporting our customers in their journey to become sustainable. You can read more about us Sustainability performance here.

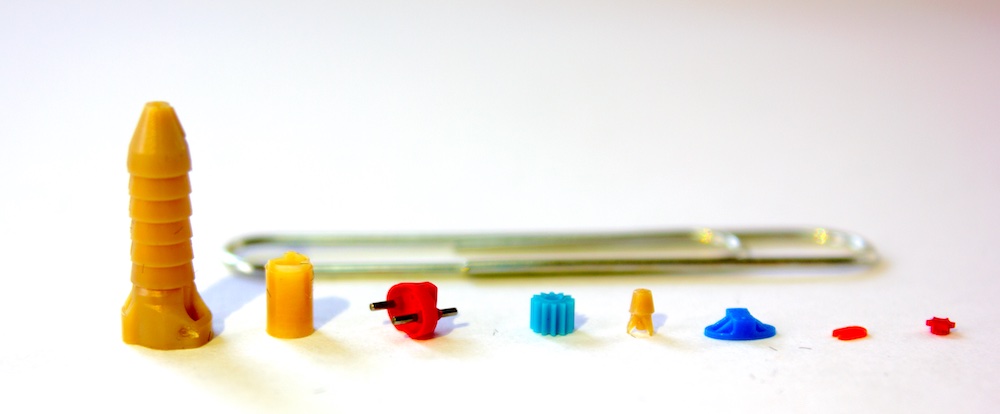

Post moulding services

The right mould tooling supplier will continue their support for a long term partnership with their customers after delivering the toolings. By maintaining strong communication and maintenance services with the mould tooling suppliers, customers can save time and effort when their toolings need services or upgrades after a certain time of running, or when they need to expand their production with mould toolings of higher cavities.

Photo: Micro moulded parts manufactured by Micro Systems

Making the right UK injection mould toolmaker choice is a crucial choice that has to be carefully thought out in relation to a number of important considerations. Prioritising knowledge, capability, sustainability, and quality management can help customers build a relationship that not only meets but surpasses your current and long-term plastic manufacturing objectives. With more than 20 years of experience, Micro Systems is the ideal injection mould tool making partner, with well-established facilities in the UK and Singapore, ready to bring your most complex projects to life with our outstanding injection mould tool manufacturing services.

Contact us to discuss your injection mould tooling project today!