Micro injection moulding in the Automotive industry

What is micro injection moulding?

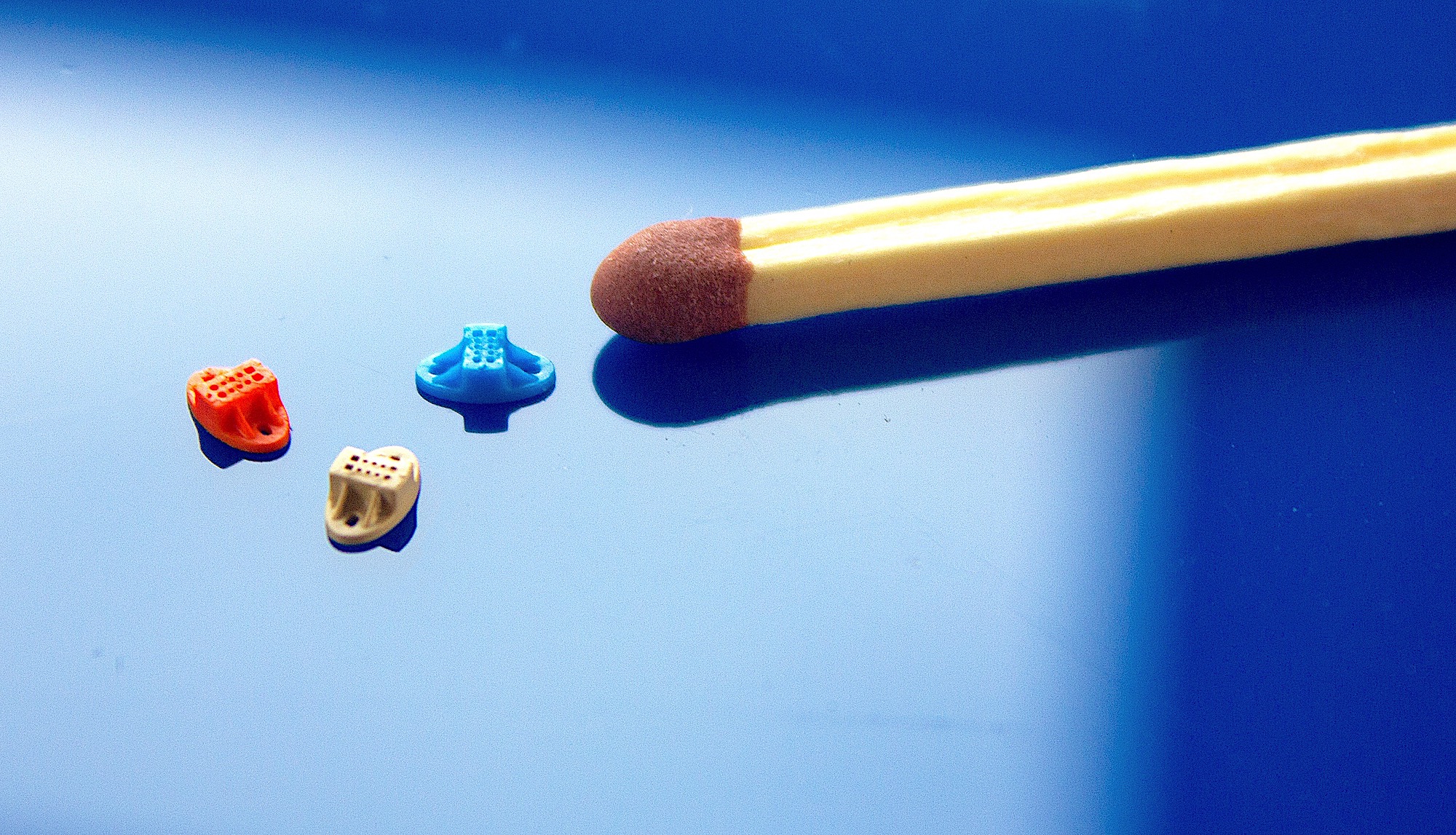

Micro injection moulding is a moulding technique used to create extremely small and precise plastic parts with micron tolerances and shot weights down to milligrams. Manufacturers can make intricate tiny geometries with the highest degree of accuracy and precision thanks to this moulding method. The micro injection moulding process first takes place in the tooling department, starting with a mould with a hollow made to resemble the desired object, followed by rapid injection of thermoplastic or resin into the cavity creating the component or part at a fast rate of speed.

Compared to other manufacturing processes, plastic injection moulding produces goods with more complex shapes, superior surface treatments, accurate tolerances, with a more cost-effective mass manufacture of thousands of identical pieces. Especially, with micro injection moulding, manufacturers can achieve extremely small and precise parts that meet the miniaturisation trend nowadays.

Micro injection moulding in the Automotive industry

The process of micro injection moulding is extensively employed in the production of lightweight and compact automotive components. Micro injection moulding is utilised for under-the-hood (engine or brake) parts of automobiles as well as for a variety of other automotive industry-relevant components, including varied clips, washers, parts for door locking mechanisms, electronic module gears and encoders, buttons (interiors and exteriors), switches, and even for the fabrication of microplastic gears.

According to a recent report, the size of the worldwide automotive market was estimated at USD 2,738,387.98 million in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 3.01% to reach USD 3,577,110.64 million by 2031, hence, the potential for micro moulding application in this industry is enormous.

Benefits of micro injection moulding in the Automotive industry:

- Mass production of complex parts with ultra-precision features and extreme accuracy

- Flexibility in plastic material options and colours

- More advanced surface finishes

- Shorter production time with high consistency

- Higher durability in challenging environments

- Can meet strict industry standards

Growing Requirement for Injection-Moulded Plastic Small Parts in Electric Vehicles

The expanding need for small injection-moulded plastic parts in the electric car industry presents substantial market prospects for the micro injection moulding industry. The automotive industry is placing a greater emphasis on electric vehicles (EVs), which has increased demand for components that are efficient and lightweight. According to a recent report, the market for electric vehicles was valued at USD 384.65 billion in 2022 and is projected to increase at a compound annual growth rate (CAGR) of 22.1% from USD 500.48 billion in 2023 to USD 1,579.10 billion in 2030. This need is fully satisfied by micro injection moulding technology, which makes it possible to produce small, complex plastic components with extreme accuracy, quality and durability. Connectors, sensors, switches, housings, and other electrical and electronic pieces in electric cars are some examples of these components. The market for micro injection moulding is expected to rise significantly as the shift to electric cars picks up steam and advances the cause of environmentally friendly transportation, encouraging more micro mould makers and micro injection moulders to take on new challenges outside the typical medical and pharmaceutical applications.

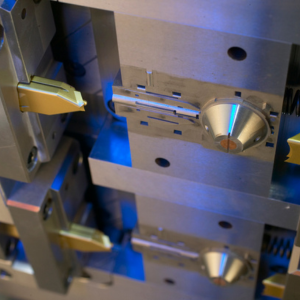

Photo: Micro injection moulding facilities in ISO Class 7 cleanroom at Micro Systems

With more than 20 years of experience in micro mould toolings and micro injection moulding, Micro Systems can take on the most challenging requirements from automotive customers, to create the smallest, most accurate possible parts from prototype to mass production. Micro Systems has in-house a team of mould and moulding experts, with the latest micro moulding machines including MicroPower and other micro metrology equipment, along with ISO Class 7 and Class 8 manufacturing environments, to support all scale automotive projects.

Contact us to discuss your micro injection moulding project!