Micro manufacturing for medical device

Thanks to micro manufacturing, complex components with previously unheard-of miniaturisation can be produced, transforming the fields of medical devices.

What is micro manufacturing?

Cutting-edge technology known as “micro manufacturing” allows for the incredibly accurate and precise creation of tiny parts, components, and structures. This area of engineering deals with the creation of extremely small components, many of which are smaller than one millimetre. Ensuring the highest quality and consistency of the finished product requires a complex design, specialised production and inspection equipment, and high-precision processes.

Common practices in micro manufacturing include advanced techniques like micro welding, micro over-moulding, micro EDM, micro insert moulding, micro assembly, etc.

Micro manufacturing applications for medical devices

Many medical devices in use today contain micromachined parts and components, which benefits from the use of micro machining. Medical devices must be compact for a variety of uses, such as medication administration, neurostimulation, and cardiac pacing, as the human body can only tolerate so many bigger components. Simultaneously, developments in technology are requiring more capabilities in smaller containers. Miniaturisation and micro manufacturing allow medical device assembly to reach previously unreachable dimensions, resulting in less intrusion and quicker healing times for patients.

Some examples include:

- Components of implantable medical devices that use microfluidic technology to regulate or stop the flow of fluids or medications

- Parts of DNA Analysis

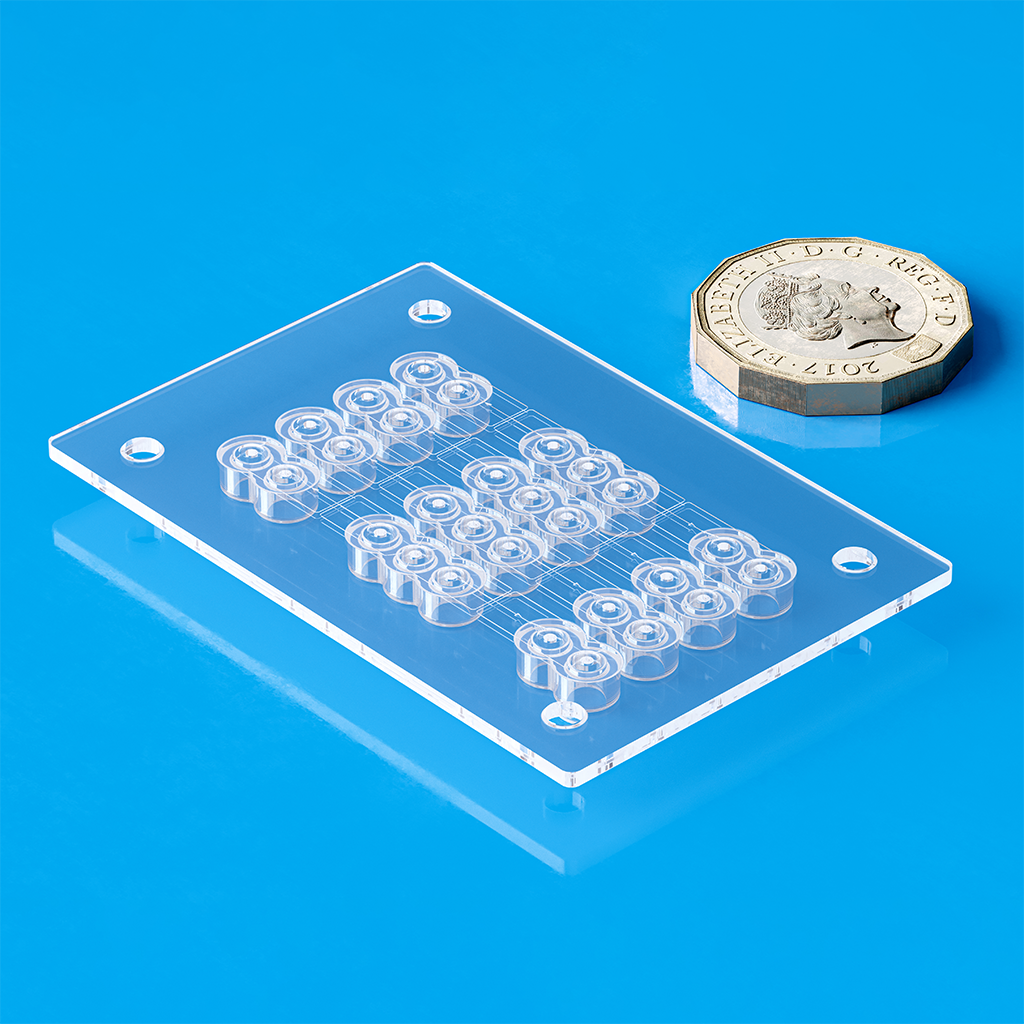

- Lab-on-a-Chip apparatus, Microfluidics chips

Micro manufacturing and micro mould manufacture

With the requirement to precisely produce medical parts in a large quantity without differences, the initial step is to design and manufacture micro moulds with the highest level of accuracy. High-speed micro milling is one of the most widely utilised micro machining processes for the production of micro moulds. During micro milling operations, a fixed workpiece’s surface is generally traversed by a diamond tool that revolves on a spindle. The tool revolves along an axis perpendicular to the workpiece as it is being milled. Depending on other factors like mould material or geometrical complexity, other micro manufacturing methods like micro EDM are also applied.

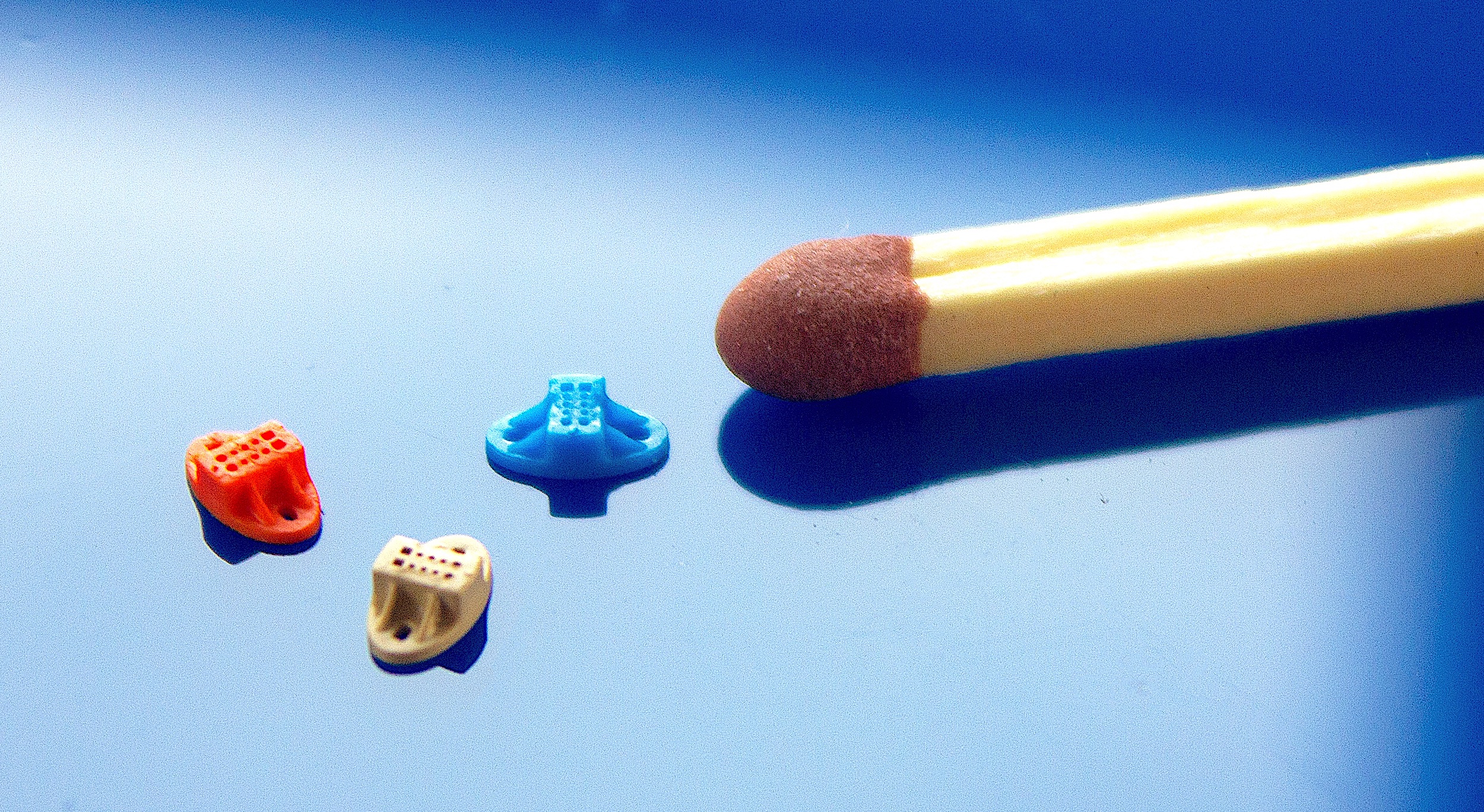

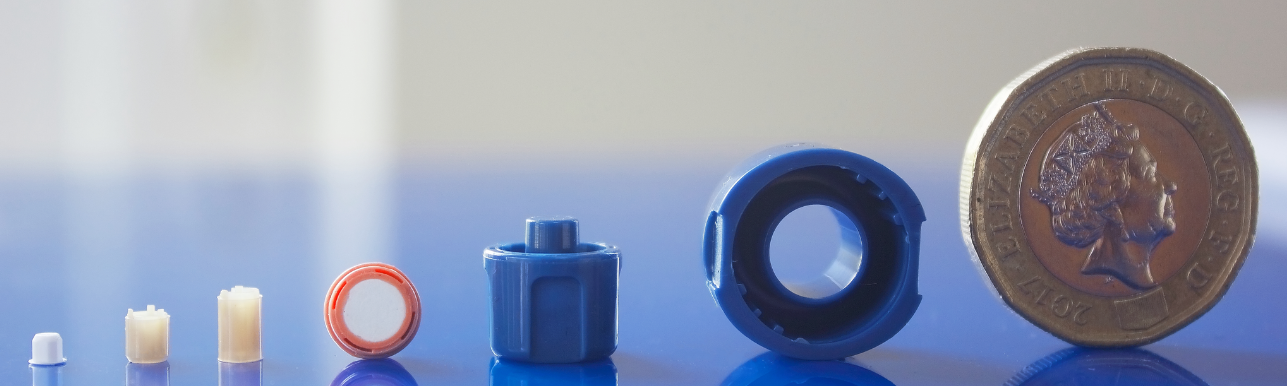

Micro Systems provides turnkey solutions for ultra-precision medical mould design and manufacture, pilot to full production mould validation. Typical component sizes range from 0.0003g – 2.5g for micro components, or up to a few hundred grams for medical device components. Some of micro manufacturing machines at Micro Systems include:

- Kern Pyramid Nano Micro Milling machines: less than 0.5 micron repeatability, less than 10 nm Ra surface finish

- EDM machines: 1 micron repeatability, 30 micron diameter wire for hardened steel cutting

- Cylindrical Grinding machines: for mould inserts manufacture for 16 and 32 cavity fast cycling ophthalmic and IOL moulds

Micro injection moulding for medical devices

Parts as small as a single pellet or weighing a fraction of a gramme can be produced using micro moulding. Micro injection moulding can also work with different types of materials, from high-performance engineered thermoplastics like PEEK, PSU or PEI, to bioresorbable materials like PLA and PLG. Micro injection moulding also brings advantages in using less raw material, fast changovers and faster cycle times. In addition, while cleanrooms are not necessary for all micro-moulded parts, medical components should be produced and packaged in a self-contained cleanroom setting in order to fulfil ISO Class 7 or 8 standards and adhere to any GMP and FDA restrictions.

Micro Systems has experience in manufacturing ultra precision injection moulded parts for the medical device and life sciences markets. Each micro-moulding production cell has a robot handling system for component separation or tray packaging via an in-line camera vision system for ‘component’ integrity and quality control prior to packaging. Some of our micro moulded products for the medical and pharmaceutical sector include:

- Bioabsorbable implant for cancer treatment

- PEEK implant

- Soft mist inhaler

- Injector pen

- Drug delivery system

- Microfluidics diagnostic system

Micro Systems also utilises our moulding expertise, the latest injection moulding technology and quality assurance to provide solutions for microfluidic analysis products. We can manufacture advanced microfluidic moulds with tolerance as low as +/-0.001mm, with integrated optics.

With more than 20 years of experience in mould design, mould manufacture and injection moulding, especially for the medical and pharmaceutical, ophthalmics, diagnostics and F&B, our team at Micro Systems can support you closely at every step of the project. We use the latest technology available on the market, together with the expertise from our experts based in the UK and Singapore, to lead your projects to success.

We are going to exhibit at COMPAMED 2023 at Hall 8a, Booth F35.3. Come visit us to discuss your medical projects!

Contact us today for more information.