Micro Moulding: Lab-on-a-chip and its applications

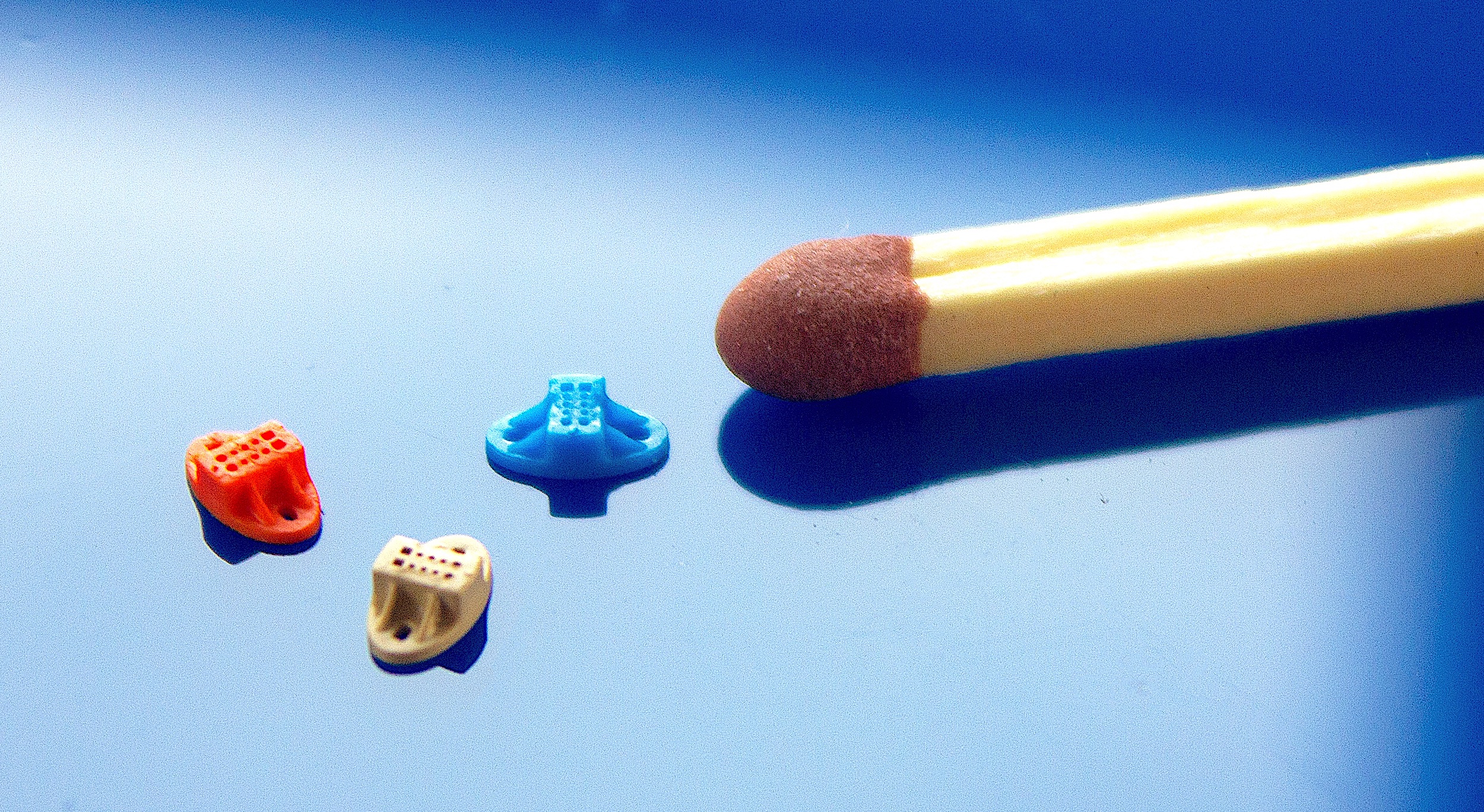

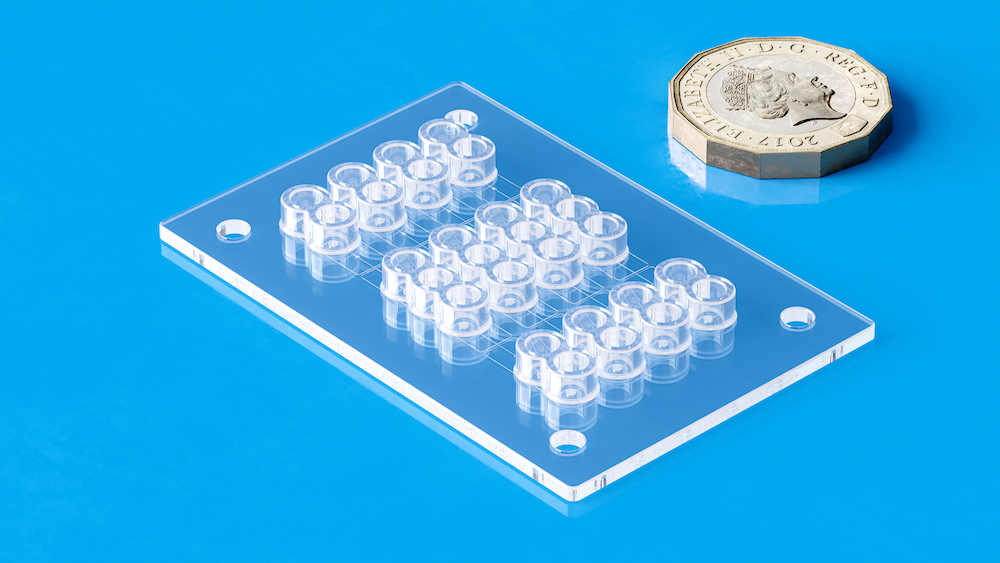

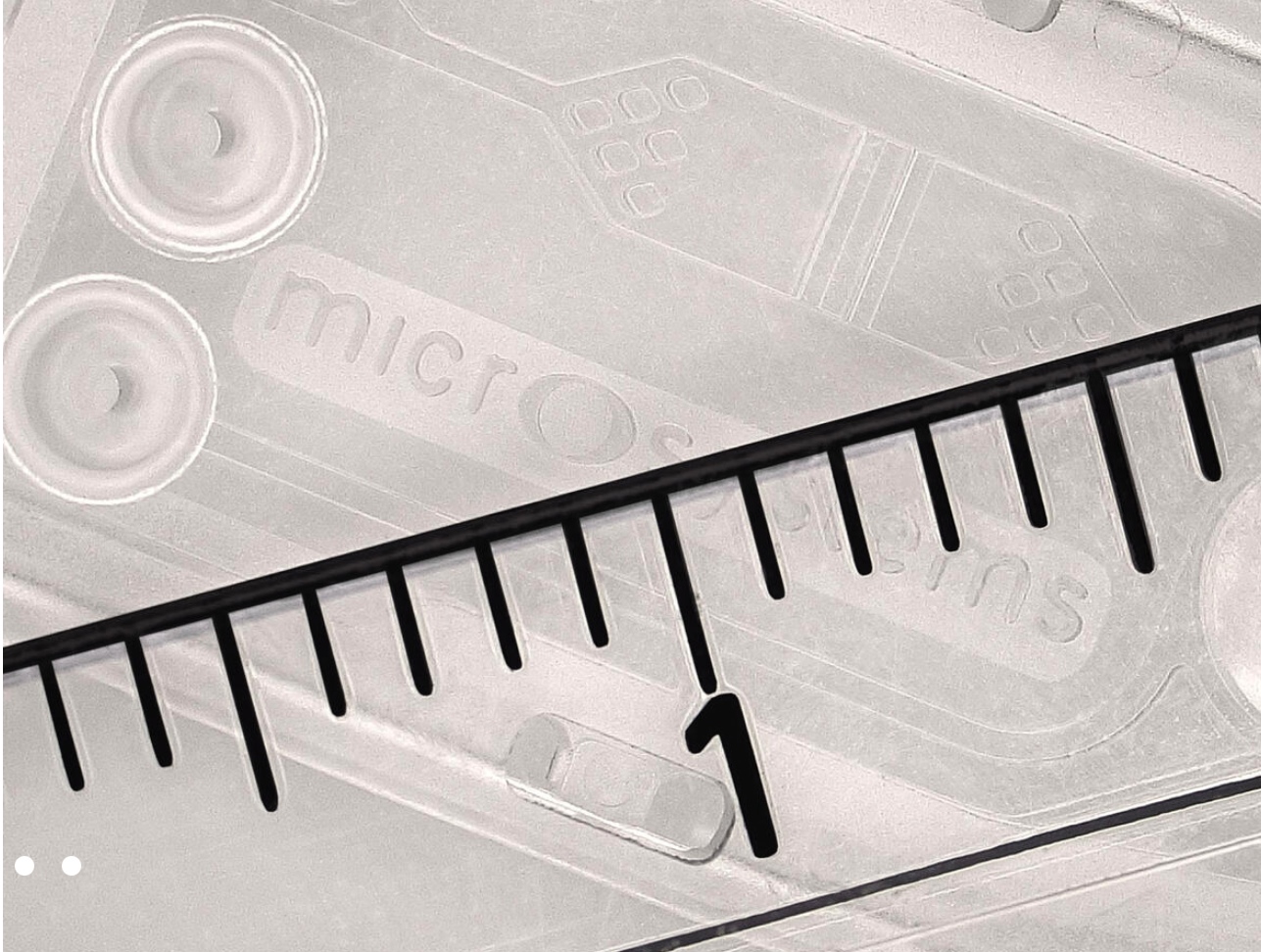

A Lab-on-a-chip with a base plate of 300 μm micro channels and chambers with static micro mixing features. The top part is characterised by three LUER cones. 2 of these connections are used to feed the liquids — 1 sample liquid and 1 reagent — to the system. Via the third LUER cone the flow rate is controlled by applying vacuum in order to reinforce the capillary effect (Photo: Micro Systems)

What is Microfluidics?

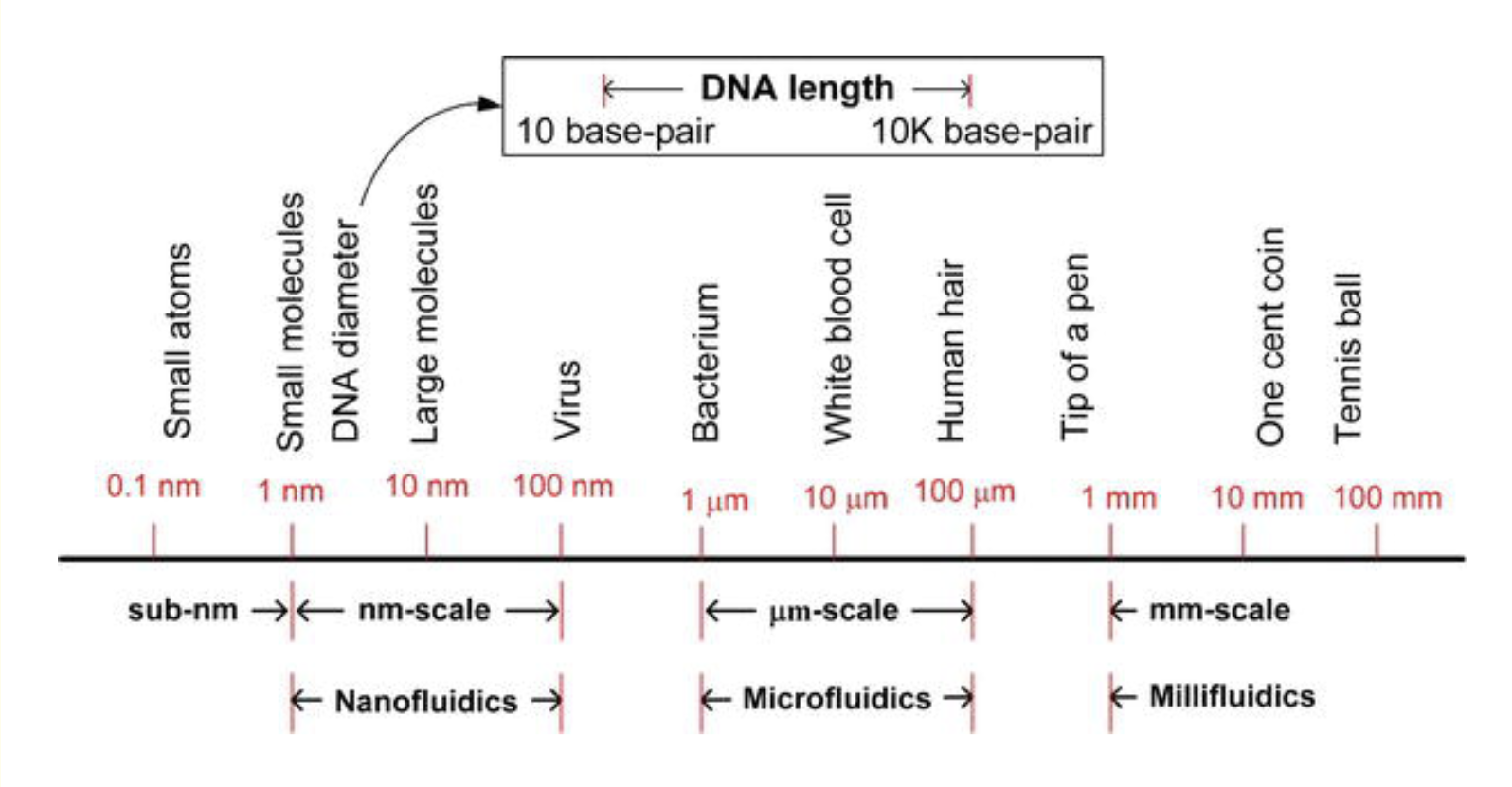

Microfluidics refers to the study of fluids at the micro- and nanoscale levels, and the technology of creating micro-miniaturised devices with chambers and tunnels through which fluids move or are constrained. Microfluidics technology works with fluid quantities as tiny as femtoliters (fL), or one quadrillionth of a liter. On a micrometric scale, fluids perform very differently from how they do in daily life, and these distinctive characteristics are crucial for new scientific research and inventions.

Microfluidics is useful for the creation of low volume fluid processing devices that enable multiplexing, automation, and high-throughput screening. Beginning in the 1980s, microfluidics was developed and is now used in the creation of multiple technologies in the fields of biotechnology, pharmaceutical engineering, patient testing and diagnostics, biodefense and chemical engineering. Common examples of microfluidics applications include but are not limited to DNA chips, lab-on-a-chip, organs-on-chips, etc. The work of an entire lab can be condensed onto a microfluidic device that is only a few centimetres in size thanks to microfluidics.

Illustrations of objects that range in size, and the distinctions between nano, micro, and millifluidics (Karanassios, 2018)

What is Lab-on-a-chip ?

A Lab-on-a-Chip (LOC) is a miniaturised instrument that combines nanotechnology and microfluidics. The channels, no thicker than a hair, are required for transporting, mixing and separating reagents down to a pico litre scale. In practice such labs are used for performing HIV tests or for blood inflammatory markers, among other applications.

Polydimethylsiloxane (PDMS) is commonly used in lab-on-a-chip prototyping for its ability to create fine surface features through cold casting. However, its mechanical properties and tendency to absorb hydrophobic molecules limit its use in industrial applications. Engineering thermoplastics such as PMMA, PS, PC, and COC are ideal alternatives, offering optical clarity, chemical resistance, and compatibility with various manufacturing and bonding methods for robust lab-on-a-chip solutions.

Processing techniques wise, cold casting, micromachining and laser ablation, 3D printing, and thermoforming (injection molding and hot embossing) are typical methods to manufacture lab-on-a-chip devices. Micro injection moulding is the ultimate choice for scaling up to industrial production, as it can produce a large number of products with outstanding surface reproduction.

Examples of applications of Lab-on-a-chip

Lab-on-a-chip helps detect viral infections, especially HIV infections, in a much cheaper, faster and less complicated way. About only 75% of more than 38 million people infected with HIV globally know that they have HIV status, and many of them are living in low-income countries where access to trained technicians and expensive equipments in laboratories for HIV test is difficult. Scientists worldwide have developed different versions of lab-on-a-chip devices that can rapidly detect HIV and MRSA, at very reasonable costs, as low as $5.

Lab-on-a-chip devices, supported by digital microfluidic analysers, enable the screening of over 6,000 rare, life-threatening diseases affecting newborns, such as those impacting the heart, lungs, and blood. These devices are especially valuable in remote areas with limited access to high-tech labs, paving the way for telemedicine applications. Designed with microscopic channels, valves, and pumps, plastic lab-on-a-chip devices can manipulate and analyze proteins, DNA, and other compounds in bodily fluids. Fluid droplets are precisely controlled using air pressure, electricity, or sound, combining with chemicals to reveal indicators of chronic diseases or pathogens.

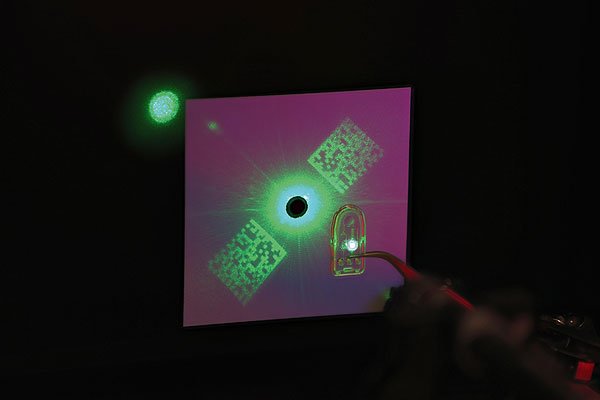

Micro Systems researched and developed a now ready for use lab-on-a-chip that can be inserted into a hand carried measuring instrument, for example for the execution of a drug test with blood or urine. Additionally, a nano structure for the hologram of a QR code could be integrated onto the end of one of the dia 0.8 mm ejector pins as a covert security verification when required. By using a laser light (laser pointer), this hologram can be made visible, significantly useful for discretely integrated counterfeiting preventive measures. With 20+ years experience in micro mold, Micro Systems achieves outstanding injection molded micro parts by replicating a nanostructure of only 300 nm (a 1/200 of a human hair).

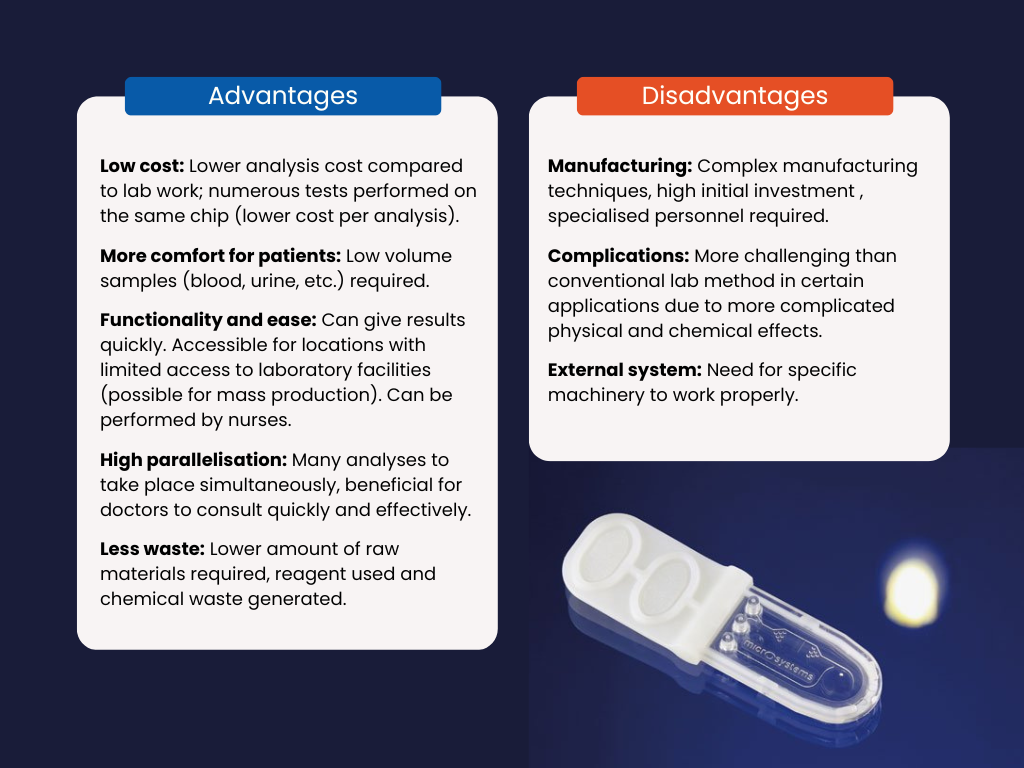

What are the advantages and disadvantages of lab-on-a-chip?

Lab-on-a-chip technology brings clinical analyses—previously limited to labs—directly to remote areas and urgent situations. Its minimal use of reagents and chemical waste offers both cost and environmental benefits. By requiring smaller sample volumes (blood, urine, saliva, etc.), it reduces patient strain. Additionally, lab-on-a-chip technology boosts productivity over traditional methods. The integration of microchannels enables high parallelization, allowing multiple analyses to run simultaneously on a single chip.

In some cases, lab-on-a-chip not only displays the ability to integrate and parallelize, but also outperforms more traditional technologies in terms of speed. For instance, the integration of PCR (a technique used to amplify DNA for pathogen identification) onto a lab-on-a-chip, known as microPCR, enables DNA to be amplified ten times more quickly than with traditional systems.

While lab-on-a-chip technology offers significant advantages, it also presents certain challenges when compared to traditional methods. At the micro- and nano-scale, factors such as surface roughness and capillary pressures play a much more critical role, potentially leading to issues like low signal-to-noise ratios, which can affect performance. As a result, lab-on-a-chip devices may sometimes yield less efficient outcomes than conventional technologies. Furthermore, many lab-on-a-chip devices are not yet fully optimised for commercialisation and industrialisation, as they often require specialised external systems to operate effectively.

Lab-on-a-chip devices have the potential to revolutionise diagnostics by enabling comprehensive patient testing in a single session, with minimal equipment and at a lower cost. By increasing the accessibility of these devices globally, medical centers could enhance their capacity to serve more patients with the same resources, facilitate early disease detection, initiate prompt treatment, and deliver targeted care without relying on rare and expensive medications.

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets. Micro Systems has developed a fully hardened 50 Rc Injection Mould Insert for production moulding of COC lab on a chip microfluidic blood analysis device. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.

References:

Karanassios, V. (2018) Microfluidics and nanofluidics: Science, fabrication technology (from cleanrooms to 3D printing) and their application to chemical analysis by battery-operated microplasmas-on-chips, IntechOpen. Available at: https://www.intechopen.com/chapters/61556 (Accessed: 22 May 2023).

Nightingale, A. and Howie, P. (2022) Lab-on-chip devices: Materials considerations, Med. Available at: https://www.med-technews.com/medtech-insights/medtech-materials-and-assembly-insights/lab-on-chip-devices-materials-considerations/ (Accessed: 22 May 2023).

(No date) A review of PDMS microfluidic chips and fabrication techniques. Available at: https://www.ufluidic.com/blogs/blog-on-chips/a-review-of-pdms-microfluidic-chips-and-fabrication-techniques (Accessed: 22 May 2023).

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.