Microneedle Drug Delivery Systems

Microneedles have burst onto the scene in recent years as a minimally-invasive, pain free and safe form of drug delivery with a range of applications from skin-care, hormone treatment, vaccinations, contraception, insulin delivery and more.

What is Microneedle Drug Delivery System?

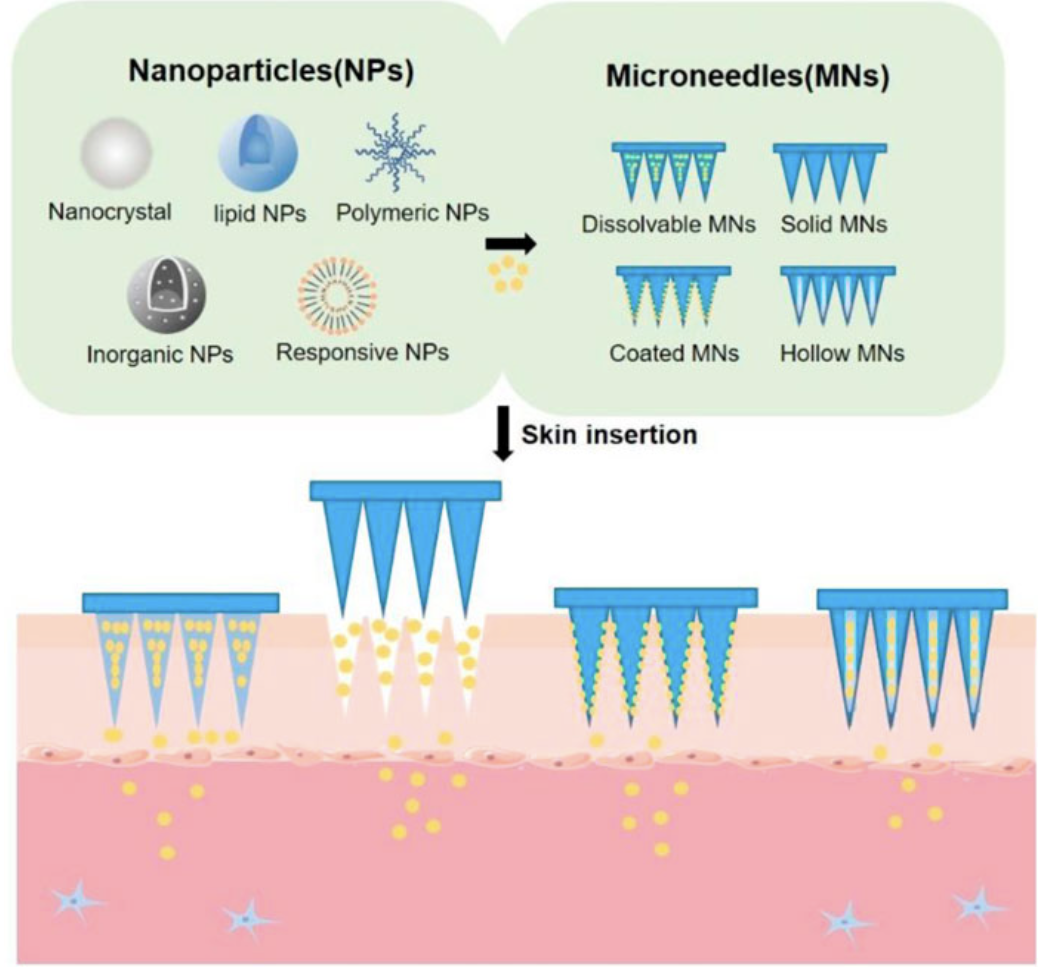

Microneedles are a collection of tiny needles that may enter the skin through the outermost layer of the skin, known as the stratum corneum, and administer transdermal drugs in a minimally invasive way (Prausnitz, 2017). Microneedle patches create reversible microchannels or dissolve beneath the skin to enable transdermal delivery of nanoparticles, overcoming the stratum corneum barrier and allowing for more efficient delivery than traditional drugs.

The schematic representation of nanoparticle transdermal distribution using microneedles, (Jiang et al., 2022)

Microneedles are used in various applications, including skincare, hormone treatment, vaccinations, contraception, and insulin delivery. Unlike traditional hypodermic needles, microneedles are small and painless, avoiding nerve endings for a more comfortable experience. They can also be self-administered discreetly, offering greater privacy and convenience.

The manufacturing and development of Microneedles

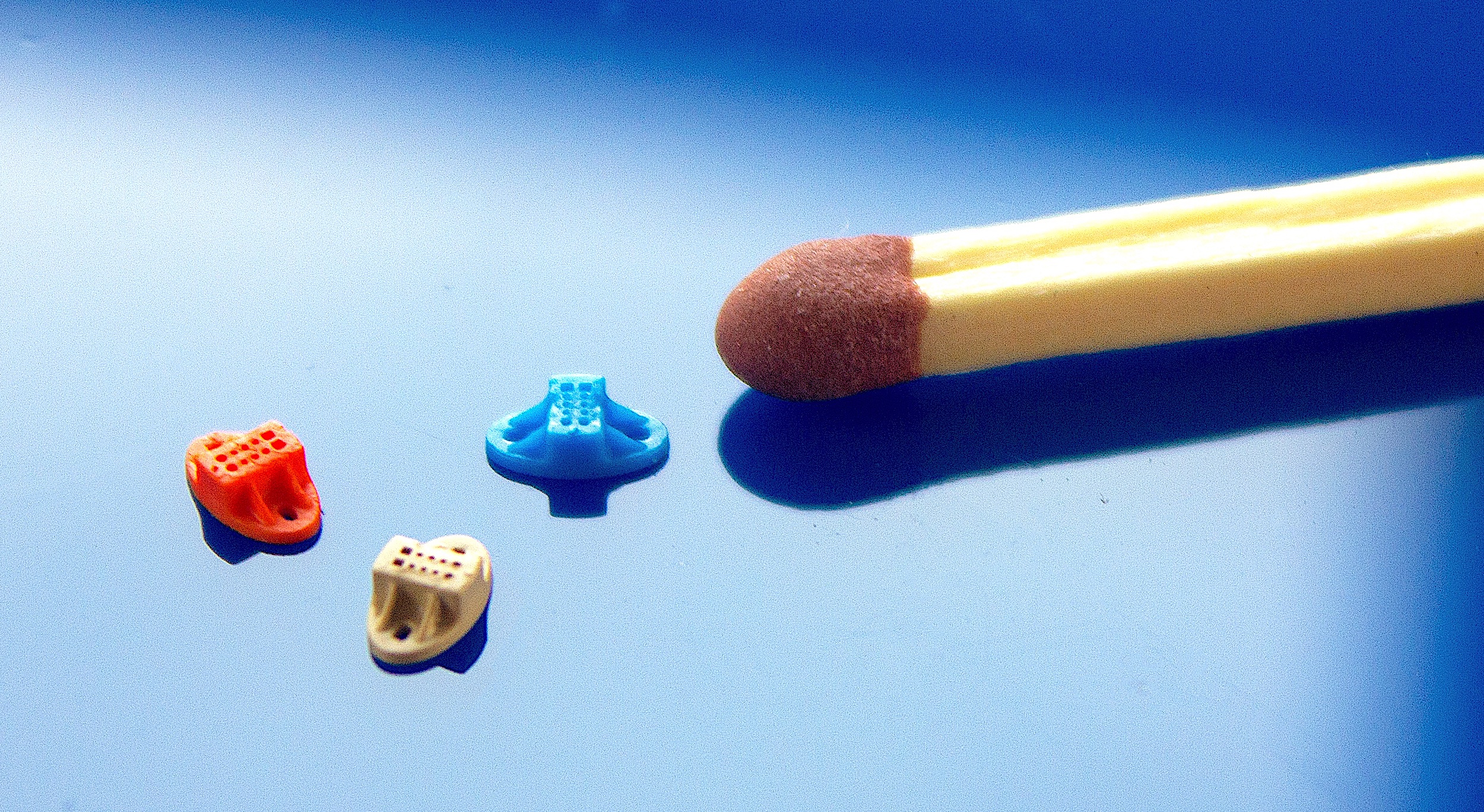

Microneedles come in a range of shapes and sizes, but they will generally be a set of tiny needles which can be pressed into the body, breaking off under the skin to release the drug. Manufacturing such tiny needles presents many challenges, not-least if they are to be produced by injection moulding. Building a mould tool with such precise, tiny features and tolerances necessary to effectively mould sharp needles with micron-level features is no simple task.

Moreover, the difficulties don’t stop with the tool itself. One of the beauties of the Microneedle technology is that the needles may be moulded in drug-laden material, meaning the needles are ‘ready-to-go’ straight off our moulding machines. However, the properties of drug-laded materials are very different to conventional thermo-plastics usually used in moulding or micro moulding, so it is certainly no easy feat to achieve within-spec parts due to the material behaving differently during the micro moulding process. As such, it is vital you choose a partner with deep in-depth knowledge and experience in moulding micro needle components.

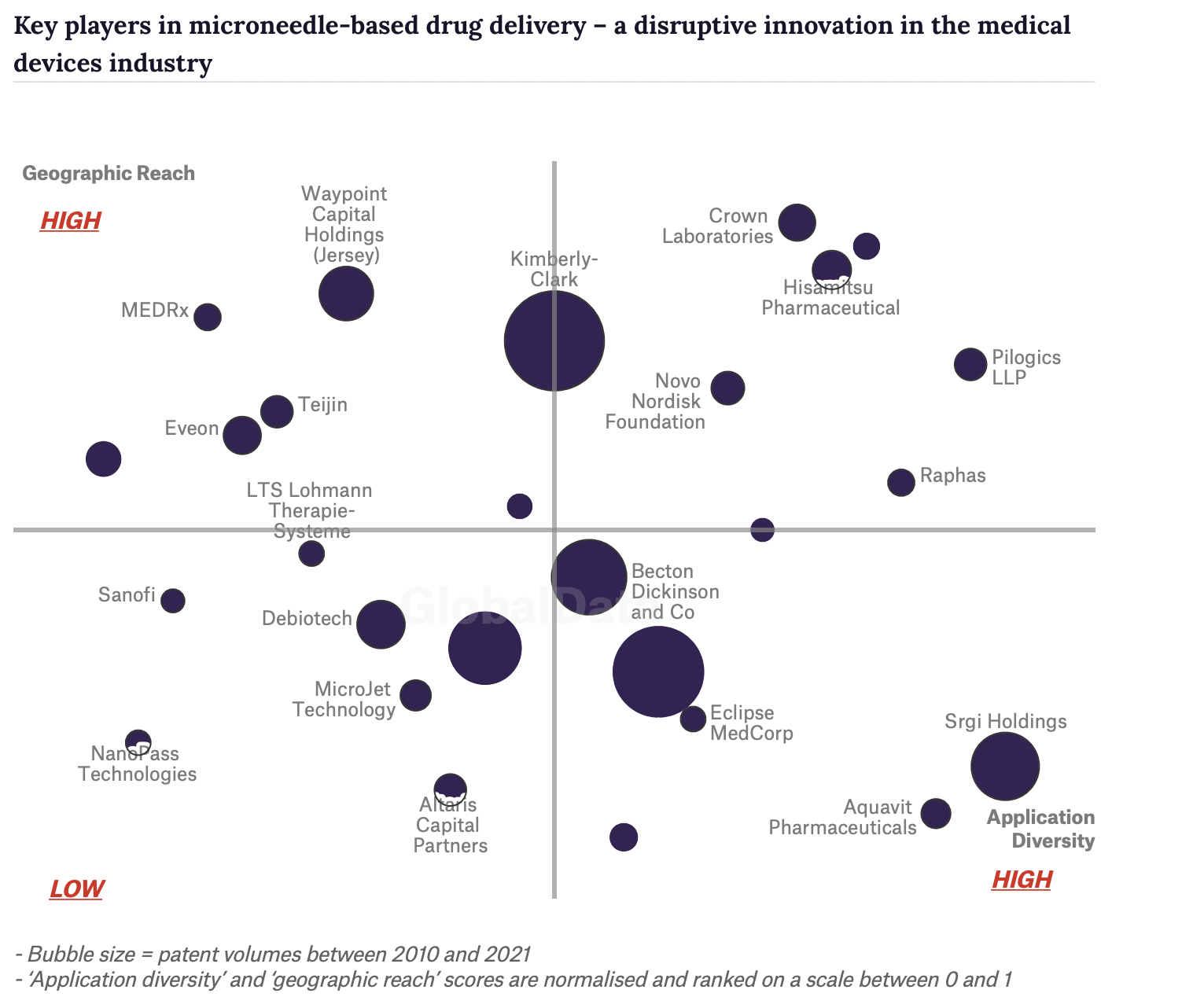

According to recent research, microneedle-based medication delivery is a key area of innovation in the medical device sector. A GlobalData study identifies over 20 companies, including established medical device firms, tech providers, and start-ups, driving advancements in this field. The study also evaluates the impact and global reach of their patenting activities across various applications.

The schematic representation of nanoparticle transdermal distribution using microneedles, (Photo: GlobalData Patent Analytics)

The market for Microneedles

According to a recently released report, the market for microneedle drug delivery systems is estimated to be worth USD 5.38 billion in 2022, and it is projected to expand at a CAGR of 7.4% from 2023 to 2030.

Microneedles are gaining popularity due to their painless, non-invasive drug delivery, improving patient compliance, reducing anxiety, and promoting treatment adherence, ultimately leading to better patient outcomes and lower healthcare costs.

In 2022, hollow microneedles accounted for over 26% of the market share, commonly used for insulin, hormone treatments, and vaccinations, due to their ability to deliver higher medication doses. Dissolving microneedles, expected to grow the fastest, are simpler and less uncomfortable than syringes and offer a biodegradable solution, eliminating waste.

In terms of materials, metal microneedles, primarily titanium and stainless steel, represented over 28% of the market share in 2022. Silicone microneedles are projected to experience the fastest growth due to their versatility in producing different needle sizes and shapes.

The medication delivery sector led with 34.9% of market revenue in 2022, driven by the increasing prevalence of chronic illnesses such as cancer, diabetes, and cardiovascular diseases.

Regionally, North America held the largest share at 43% of total revenue in 2022, with a strong pharmaceutical sector driving microneedle adoption. In the Asia-Pacific region, the market is expected to grow at a CAGR of 8.2%, fueled by rising healthcare costs and increased investment in R&D.

At Micro Systems, we have been at the forefront of R&D in the Microneedle industry, and we have been able to develop our own techniques and trade secrets to overcome common problems which occur when manufacturing moulds and moulding micro needles, such as gas build up at the needle tip, ejection difficulties or unusual material behaviour. When it comes to a challenging microneedle project, Micro Systems has the confidence and the competence to assist medical manufacturers, Life Science companies and healthcare organisations in achieving their most challenging requirements.

References:

Prausnitz, M. R. (2017). Engineering Microneedle Patches for Vaccination and Drug Delivery to Skin. Annu. Rev. Chem. Biomol. Eng. 8, 177–200. doi:10.1146/annurev-chembioeng-060816-101514

Jiang, X., Zhao, H. and Li, W. (2022) ‘Microneedle-mediated transdermal delivery of drug-carrying nanoparticles’, Frontiers in Bioengineering and Biotechnology, 10. doi:10.3389/fbioe.2022.840395.

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.