Mould Manufacture

UNMATCHED ULTRA-PRECISION MOULD MANUFACTURER

Micro Systems’ in-house toolmakers in the UK and Singapore ensure precision mould manufacturing with top-quality processes for unmatched accuracy. Our machining capabilities include:

|

|

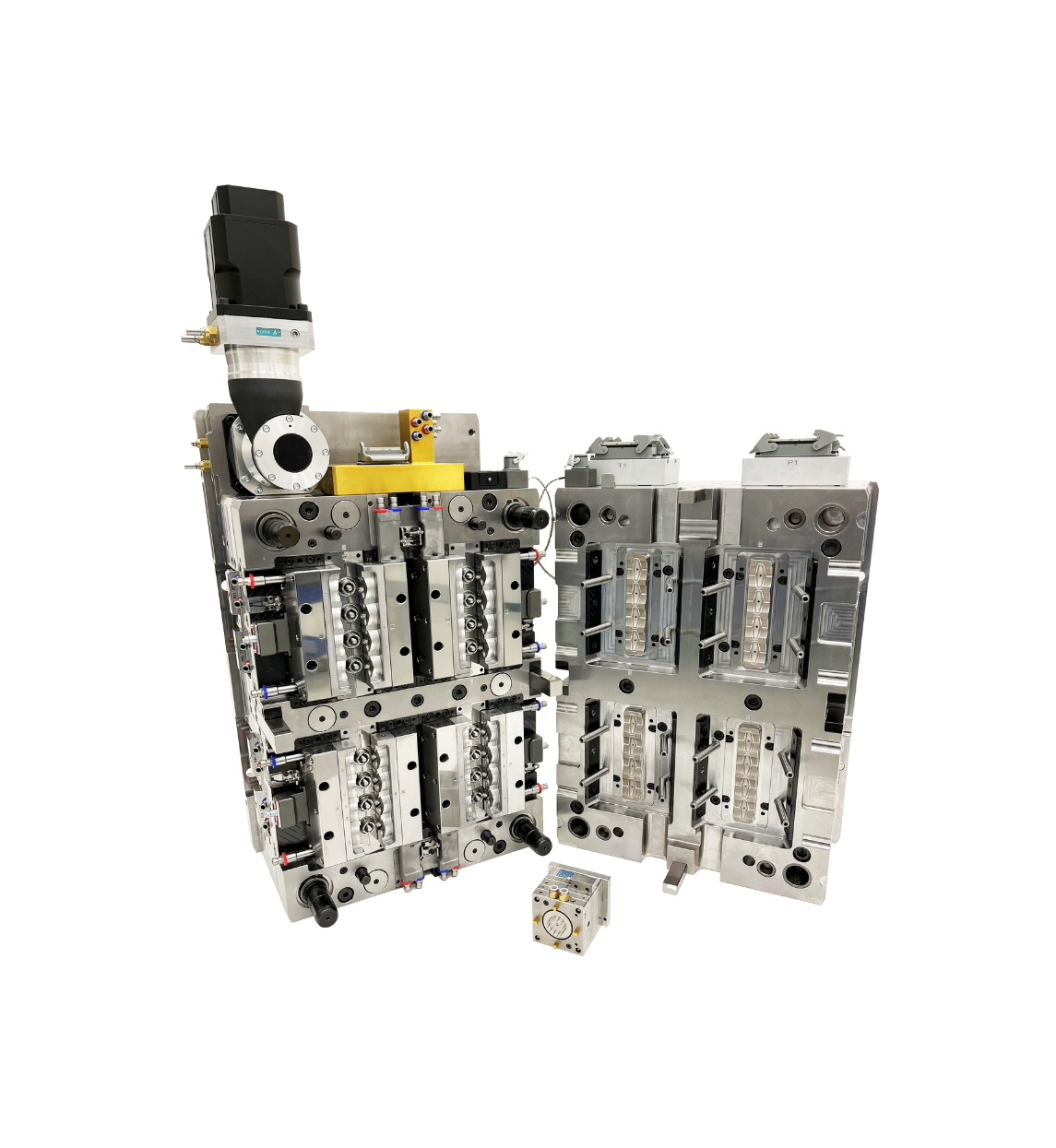

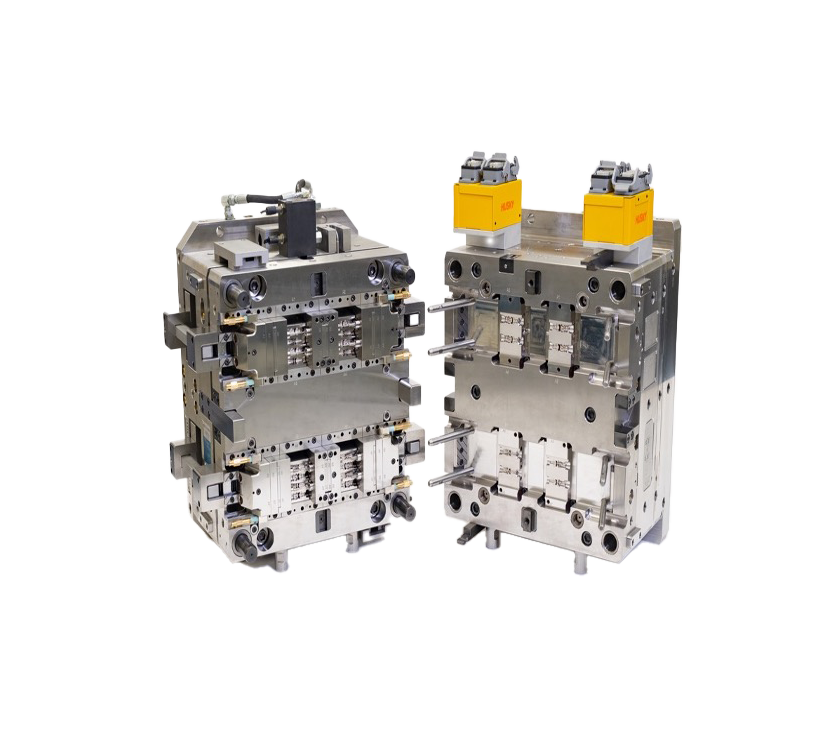

We provide custom complex, precision, multi-cavity mould tooling that meet all of your requirements:

|

|

ULTRA PRECISION MACHINING

Micro Systems produces optical inserts for both conventional and micro moulds, machining mirror finishes directly into hardened steel inserts – no additional operations required.

MICRO MILLING

Our KERN Pyramid Nano can machine fully hardened steel using cutters as small as 50 microns in diameter (0.002″), with is advanced 5-axis, and a spindle speed of 55,000 RPM.

GRINDING

We can work from small to large workpieces in single, small and large series production, for mould inserts manufactures for 16 and 32-cavity fast cycling ophthalmic and IOL moulds.

MICRO EDM & WIRE EDM

We can cut through hardened steel with a wire diameter of 30 microns (0.0013″) and a positional accuracy of 0.001mm (0.00004″).

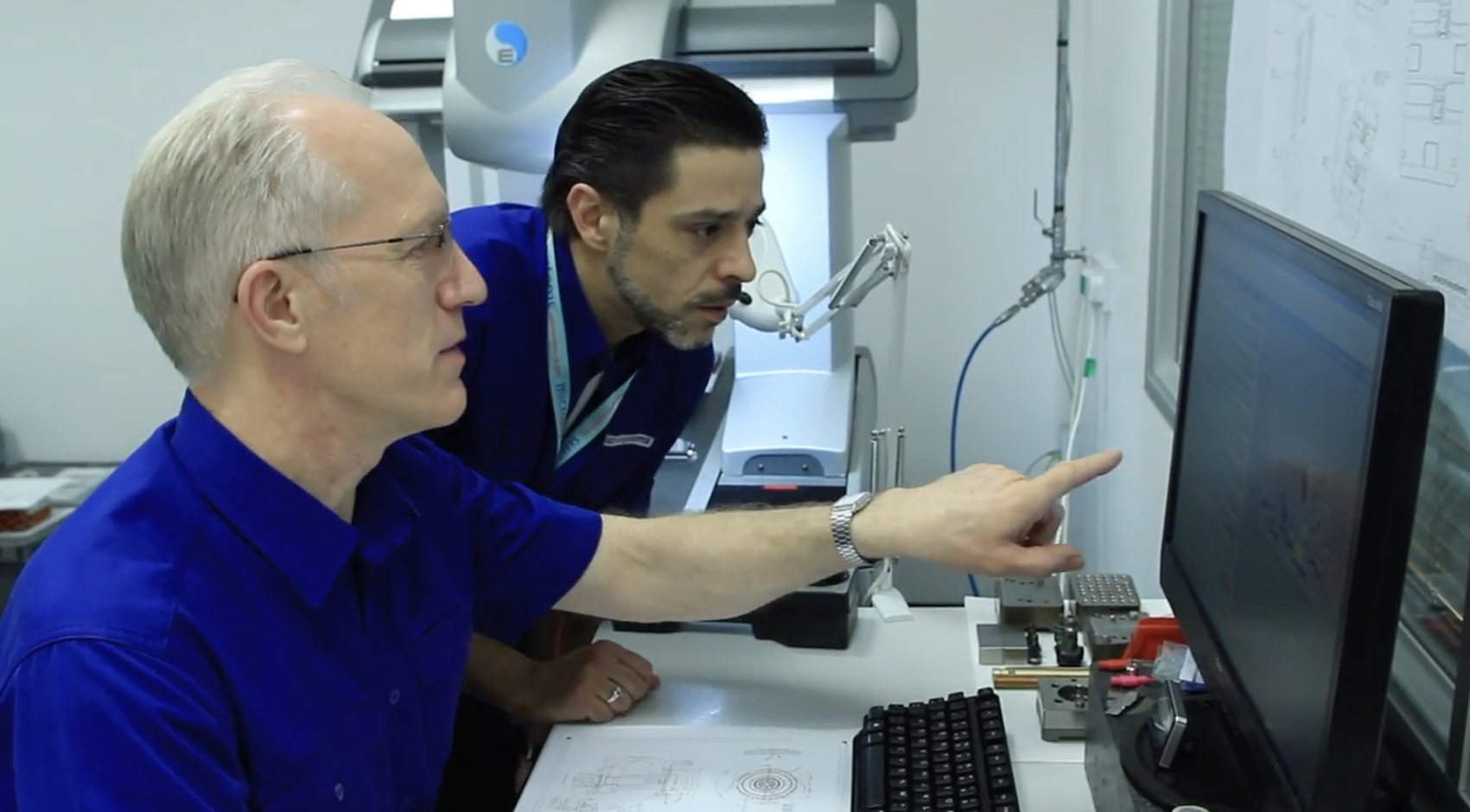

TOP-QUALITY IN-HOUSE TOOL-MAKING FACILITIES

In the UK and Singapore, we invest in cutting-edge technology to deliver top-quality mould tooling efficiently for our customers. Our machines include:

Kern Pyramid Nano Micro Milling machines: less than 0.5 micron repeatability, less than 10 nm Ra surface finish

EDM machines: 1 micron repeatability, 30 micron diameter wire for hardened steel cutting

Cylindrical Grinding machines: for mould inserts manufacture for 16 and 32 cavity fast cycling ophthalmic and IOL moulds

We offer mould maintenance services to maximise the lifespan of our moulds throughout their lifetime.

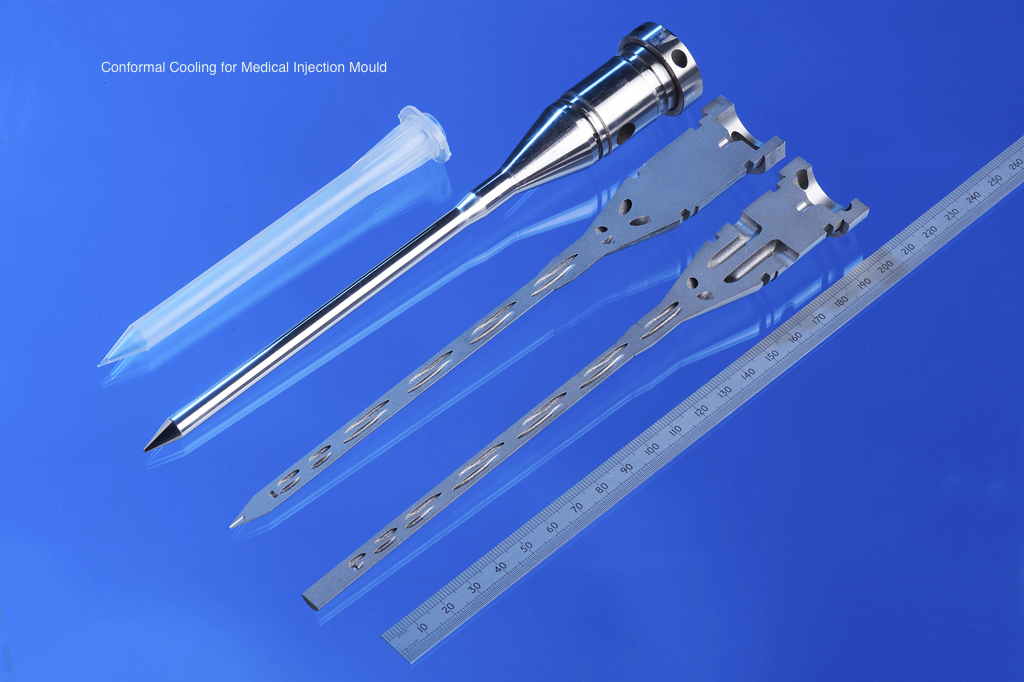

UNLIMITED INNOVATION

Micro Systems drives innovation with cost-effective tooling solutions to maximise both financial and technical benefits for our customers. For example, our Conformal Cooling channels for medical injection moulds reduce the cycle time of a medical packaging part from 6.5 seconds to 3.5 seconds.

FROM RAPID PROTOTYPING TO MASS MANUFACTURING

Micro Systems delivers fast, efficient prototypes to help verify your project’s future. Our experienced team supports you through every step of on-demand mould projects to ensure the highest quality standards.