PEEK micro moulding for medical implants

What is PEEK?

PEEK, polyether ether ketone, is a colourless organic thermoplastic polymer belonging to the polyaryletherketone (PAEK). PEEK is a semicrystalline thermoplastic that retains its high-temperature mechanical and chemical resistant qualities quite well. Due to its remarkable qualities and biocompatibility, Medical Grade PEEK is a high-performance thermoplastic that is becoming more and more popular in the medical sector.

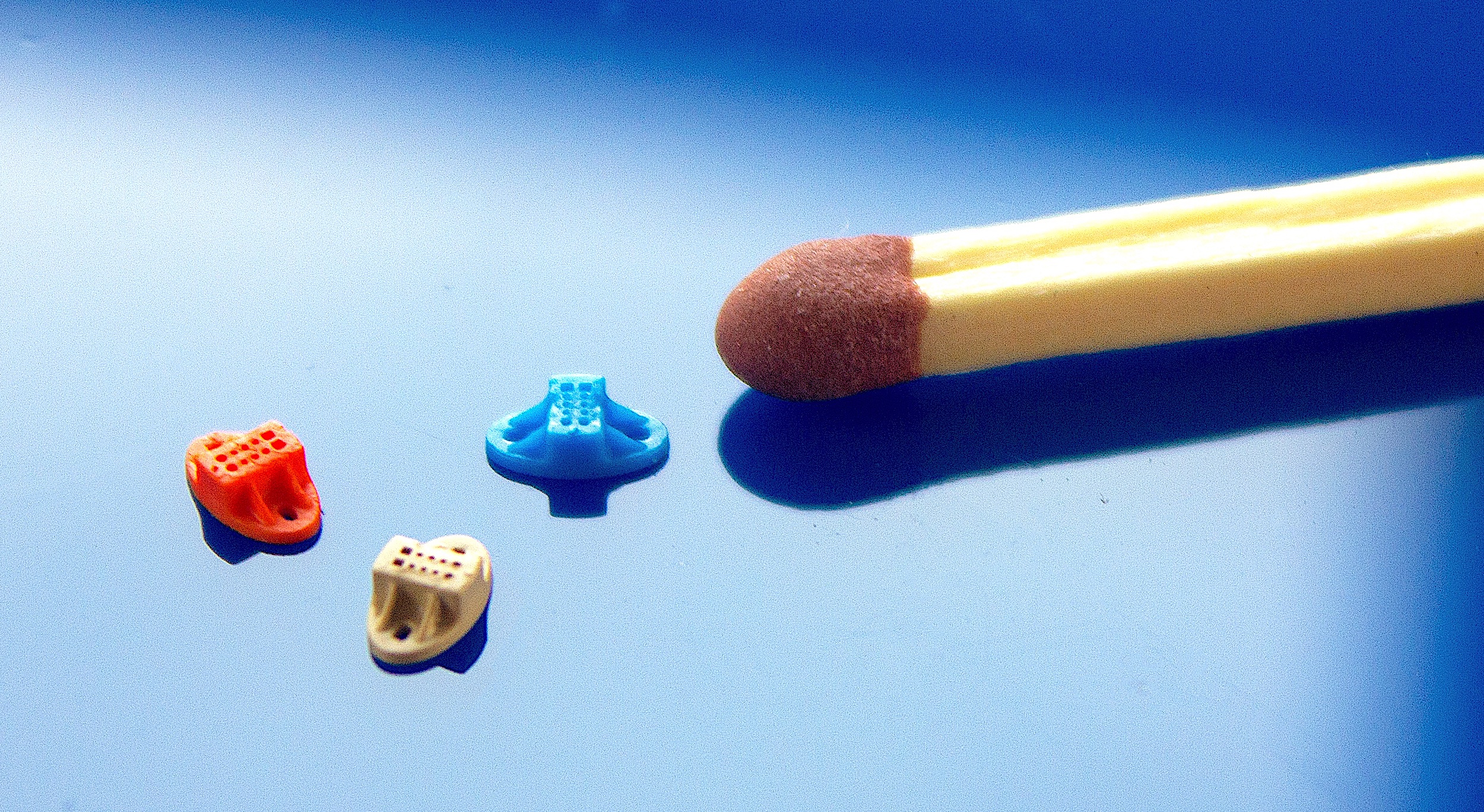

Photo: PEEK implants by Micro Systems

What are medical implants?

Artificially created devices, known as medical implants, are inserted into the body for extended periods of time and serve various medical functions. Medical implants are useful for restoring bodily function as well as for treating and monitoring medical problems.

A large number of implants are prostheses meant to replace lost bodily components. Some implants maintain organs and tissues, monitor physiological processes, or provide medicine. Implants can be put in place permanently or taken out when no longer required. Stents and hip implants, for instance, are meant to last a lifetime, while chemotherapy ports or screws used to fix shattered bones can be taken out.

According to a recent report, the size of the global medical implants market is anticipated to increase at a compound annual growth rate (CAGR) of 7.20% from USD 111.33 billion in 2023 to USD 157.62 billion by 2028. The main drives come from the growing number of elderly people, the prevalence of chronic illnesses, the need for cosmetic dentistry, and the development of medical implants through technology.

PEEK and Medical implants

The usage of polyetheretherketone (PEEK), which can occasionally replace metal, is becoming more and more accepted for use in implanted devices. Compared to metals, PEEK has better biocompatibility and mechanical qualities (tensile strength and flex modulus). PEEK also offers improved load-bearing capacity and a lower risk of stress shielding because of its mechanical qualities, which are similar to those of human bone in terms of high strength, durability, and fatigue resistance. Additionally, PEEK is radiolucent, which enhances visibility in medical imaging to assess the bone’s healing process—for instance, during cancer surgery.

PEEK and Medical micro moulding

Micro moulding is a precise technique that creates parts of tight tolerance, extremely small size and precision. With its advantages in costing, precision, durability and sterilisation, micro moulding is a preferred technique for medical device production. However, with several challenges in moulding PEEK material, only certain micro moulders with extensive experiences in micro moulding could take on PEEK projects for medical purposes.

For registration in the US or Europe, medical devices that are meant to come into prolonged touch with bodily tissues must fulfil extremely strict quality standards, hence micro moulders are required to show how they guarantee consistent quality in addition to proving that the raw materials are appropriate for the intended use. For instance, the material characteristics of PEEK are affected by varying cooling rates during injection moulding processes, and the length of time and temperature at which the heat treatment is applied directly affects the PEEK polymers’ crystallinity and, therefore, their mechanical characteristics. Stabilising all pertinent process parameters during micro moulding is crucial to achieving only high-quality components for medical implants throughout an extended manufacturing period.

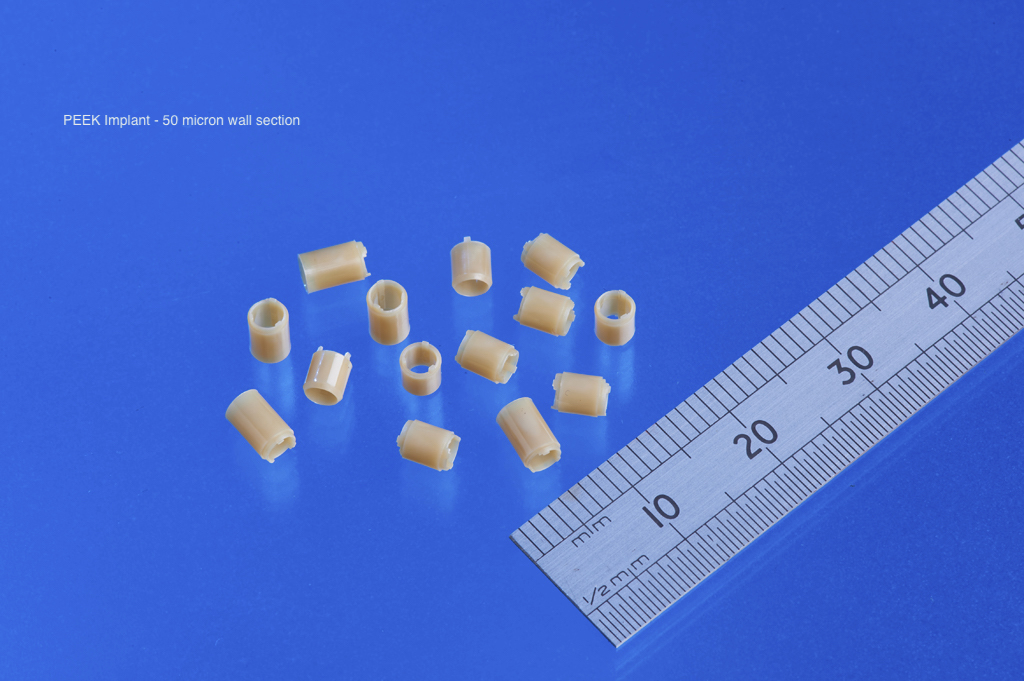

Photo: PEEK implants by Micro Systems

It is possible to solve some of the PEEK moulding process’s issues at the mould design phase. Controlling temperature and preventing thermal expansion are difficult due to the high mould temperature needed to attain crystallinity. Achieving dynamic thermal stability as soon as feasible is the aim, mainly by maintaining the lowest feasible mould mass.

Depending on the PEEK type and flow length, it is possible to achieve micro components made of PEEK with wall thickness less than 150 µm. In order to produce a reliable process, experienced micro moulders usually advise choosing the largest injection point size feasible; nevertheless, for tiny components, there is sometimes insufficient room to construct an ideal gate. In PEEK, gate point dimensions less than 0.2 mm are crucial and need to be investigated in a real test.

ISO Class 7 cleanroom facilities at Micro Systems for medical micro moulding

Micro Systems has been successfully processing PEEK for various applications for many years. These applications range from thin wall to 5 mm wall thickness and from component weight of 0.001 gramme to more than 1 gramme. At Micro Systems, we have the know-how to offer advice on your design and refine the moulds to guarantee the highest quality and the most effective production procedure. We heavily invest on our in-house mould designers and machine operators, as we strongly believe that the quality of the finished PEEK medical implants rely greatly on the operator’s skill and the accuracy of the moulds.

Micro Systems is an ISO 9001 and ISO 13485 certified subcontractor of high precision micro components. We specialise in the medical industry and offer a full range of services from part design to fully automated mass manufacturing. Micro Systems provides entirely automatically production in ISO Class 7 clean rooms in the UK using bioresorbable and high-temperature materials such as PEEK.

Contact us today to discuss your PEEK medical implants projects!