Single-cavity and Multi-cavity Injection Moulding

When it comes to injection moulding, it is important for engineers and designers to make the ultimate decision on cavity number, single-cavity or multi-cavity mould, mainly based on the timeframe and quantity demanded, hence seldom interchangeable.

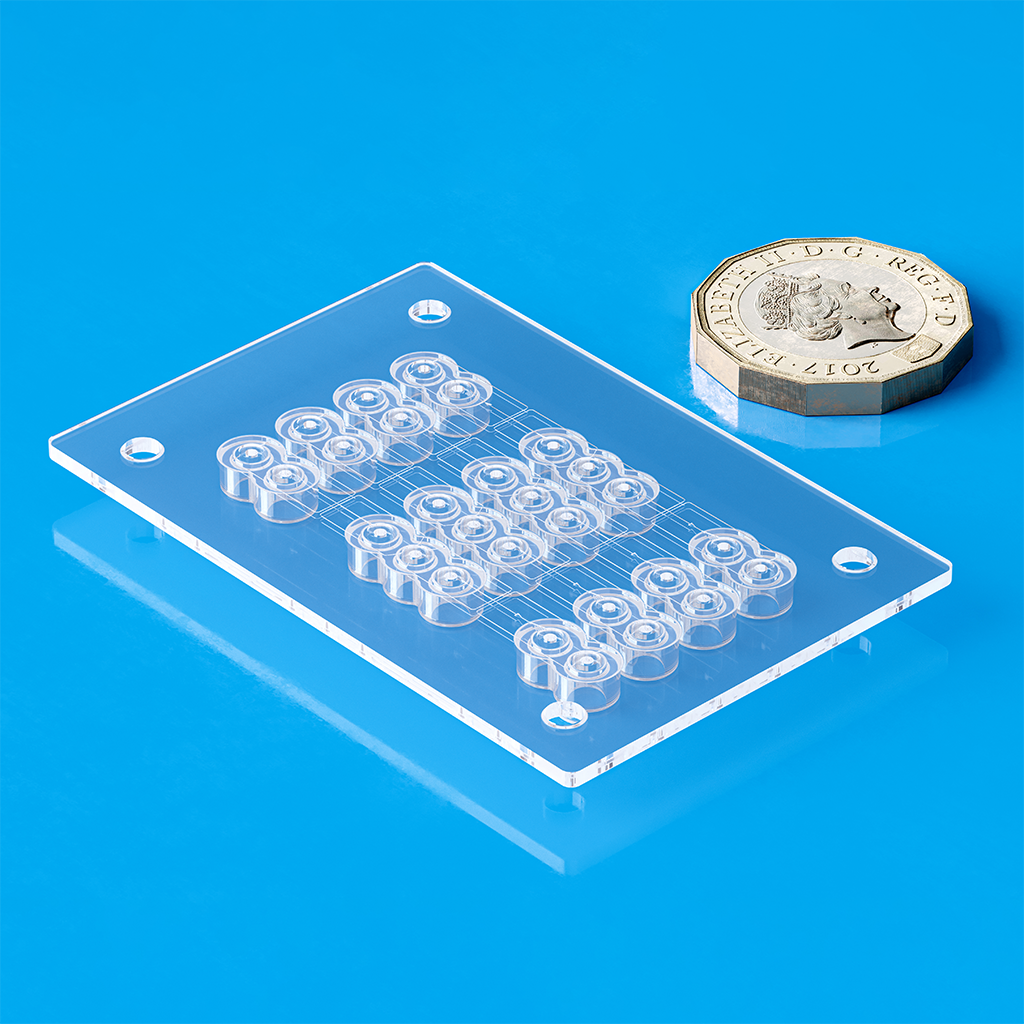

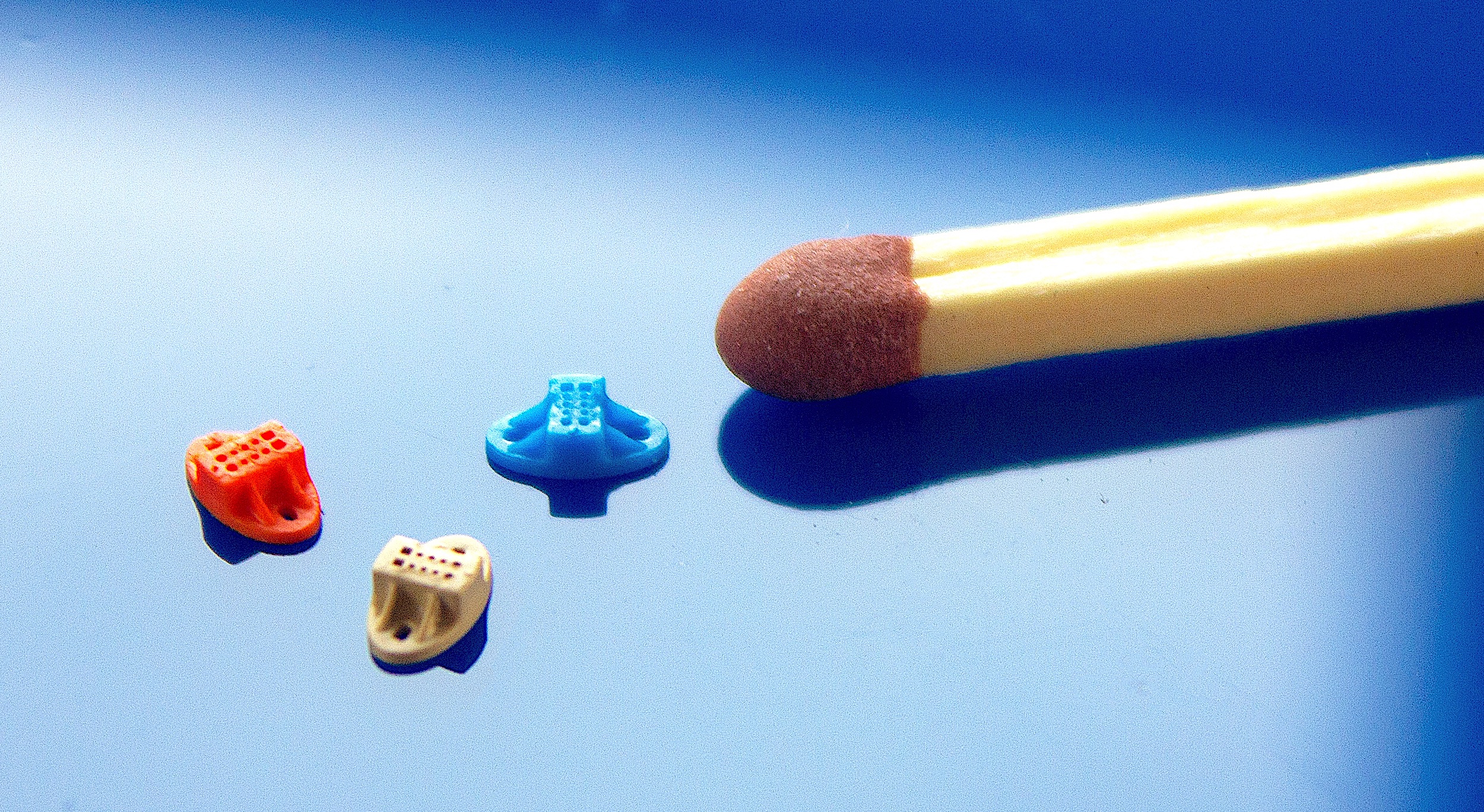

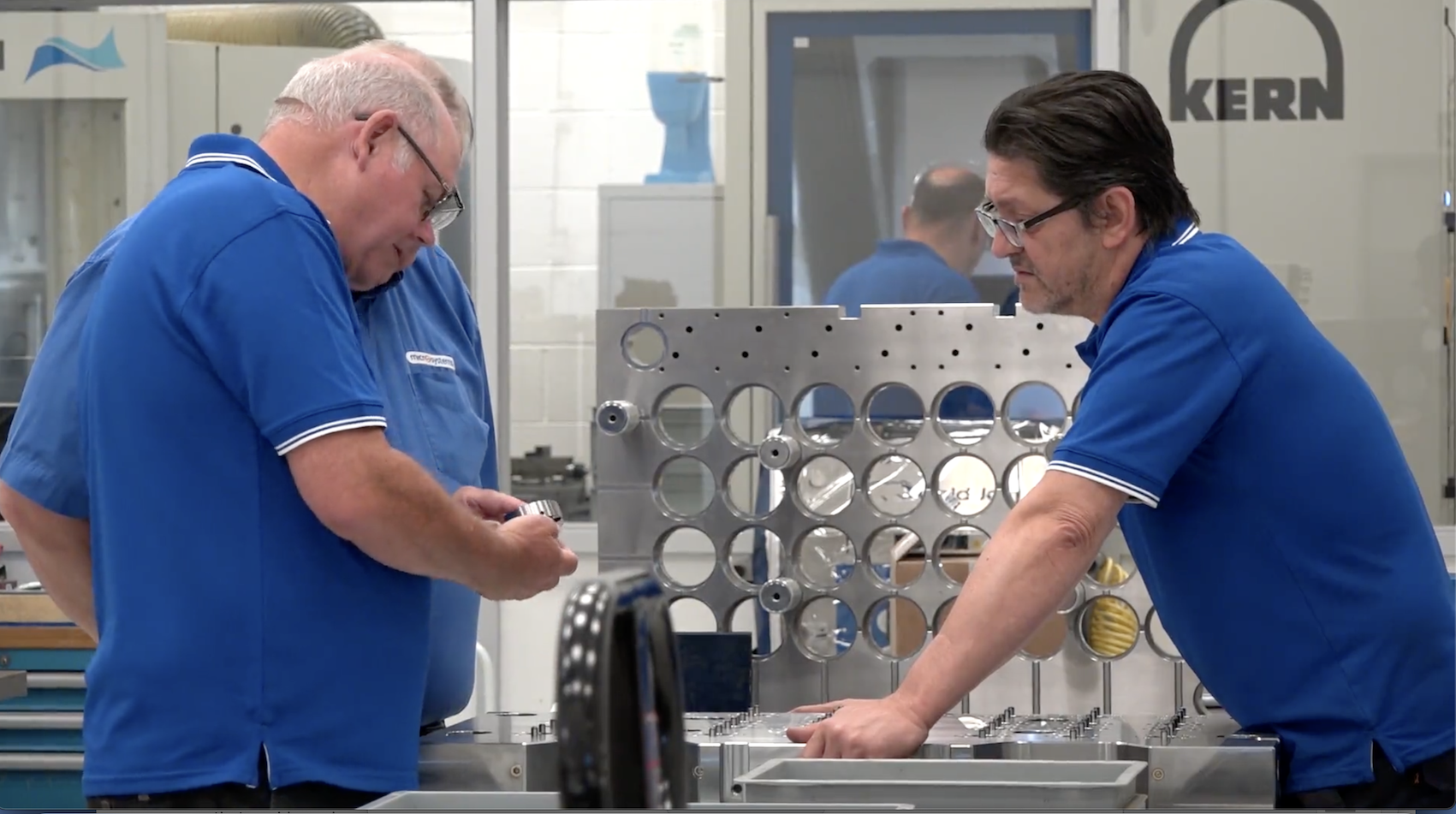

The choice of mould’s cavity number has a significant impact on the cost-effectiveness and productivity of the final product (Photo: Micro Systems)

What is a Cavity in a mould?

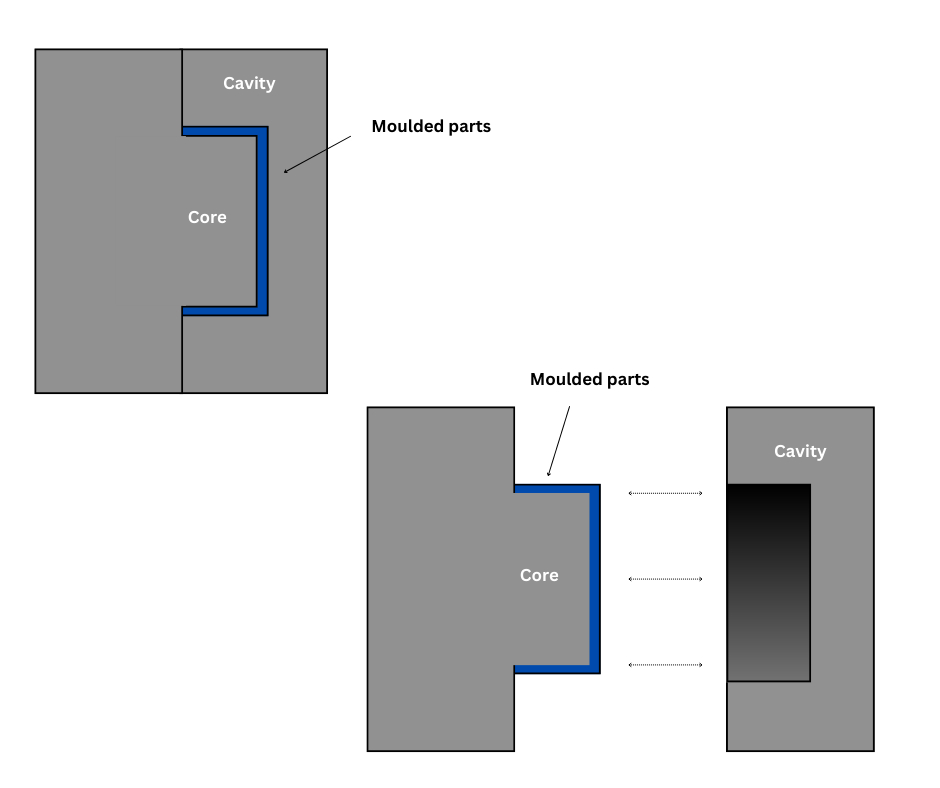

An injection mould consists of two main components: the core and the cavity. The core represents the raised portion of the mould, while the cavity is the recessed section. During the injection moulding process, molten plastic material is injected into the space between the core and cavity, where it solidifies into the final shape. The design of the core and cavity is critical to the successful moulding of the product, determining both its shape and appearance.

Once the mould has been created, the production process can now start. The mould’s cavity and core are first clamped, or pushed, together, then comes the process of injecting molten plastic into the mould. After settling and cooling, the plastic can fill the mould and solidify. Finally, ejector pins release the item from the mould when it opens, and the final moulded product could be collected for the next steps.

Single-cavity or Multi-cavity mould?

The main difference between single-cavity and multi-cavity moulds is simply the number of cavities within the mould. Since there is only one cavity for plastic resin injection, single-cavity moulds only manufacture one product every cycle.

Multi-cavity moulds, on the other hand, feature at least two cavities and two cores, all identical and produced in symmetrical pairs with even numbers, with a theoretical upper limit of hundreds of microscopic cores and cavities. Due to the abundance of cavities, with multi-cavity moulds, a single manufacturing cycle can produce dozens or even hundreds of completed pieces, depending on the moulding machine’s capability.

Benefits of Single-cavity mould

- Single-cavity injection moulds are generally less expensive to produce than multi-cavity moulds as the former could be smaller hence take less material and product cost to make.

- Single-cavity moulds could be more simple to make and design, hence the lead time is shorter to get the mould, suitable for rapid manufacturing methods.

- Can produce both small and large size parts

- Plastic injection moulding operations are easier to manage with single-cavity moulds, improving product quality. Unlike multi-cavity moulds, issues in one cavity do not affect others.

Benefits of Multi-cavity mould

- Shorter production time for the desired number of parts required, as multi-cavity moulds could make many items with a single mould.

- Multi-cavity moulds utilise cycle time more efficiently, producing more parts with the same mould within the shot guarantee, hence significantly suitable for large-volume production.

- Multi-cavity moulds can produce a cheaper per-unit moulding cost (while the initial mould cost could be more expensive) as multiple parts are produced in a unit time.

- Multi-cavity moulds could raise the consistency and quality control for mass production, as they reduce the chances of having defects compared to producing the number of parts using different single-cavity moulds.

- A eight-cavity mould could have a lower total cost of ownership (TCO) to make than eight separated single-cavity moulds.

- Multi-cavity moulds could save space within the manufacturing facilities as they are smaller compared to the number of single-cavity moulds to make the same amount of parts in the same amount of unit time.

Key takeaways

The choice between single-cavity and multi-cavity moulds depends on factors such as part complexity, machine capacity, and tooling cost. Multi-cavity moulds are ideal for high-volume production but come with higher initial costs, longer lead times, and increased maintenance. Single-cavity moulds are more cost-effective for short-run projects or when part quality is critical. Customers should collaborate with mould designers to ensure the most suitable mould type is selected to optimise cost and project timelines.

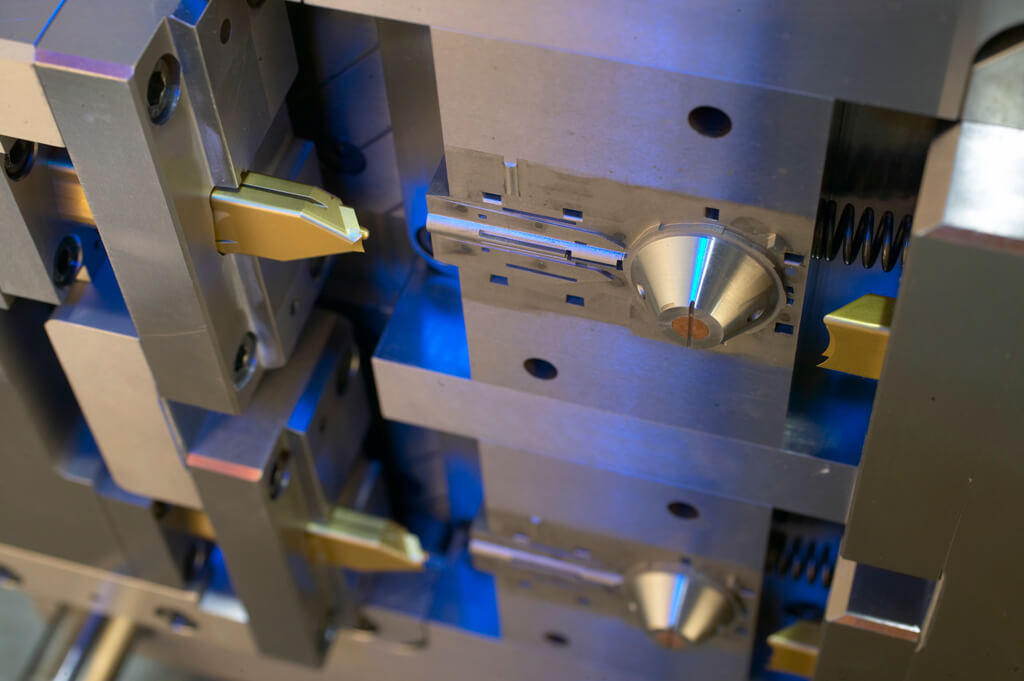

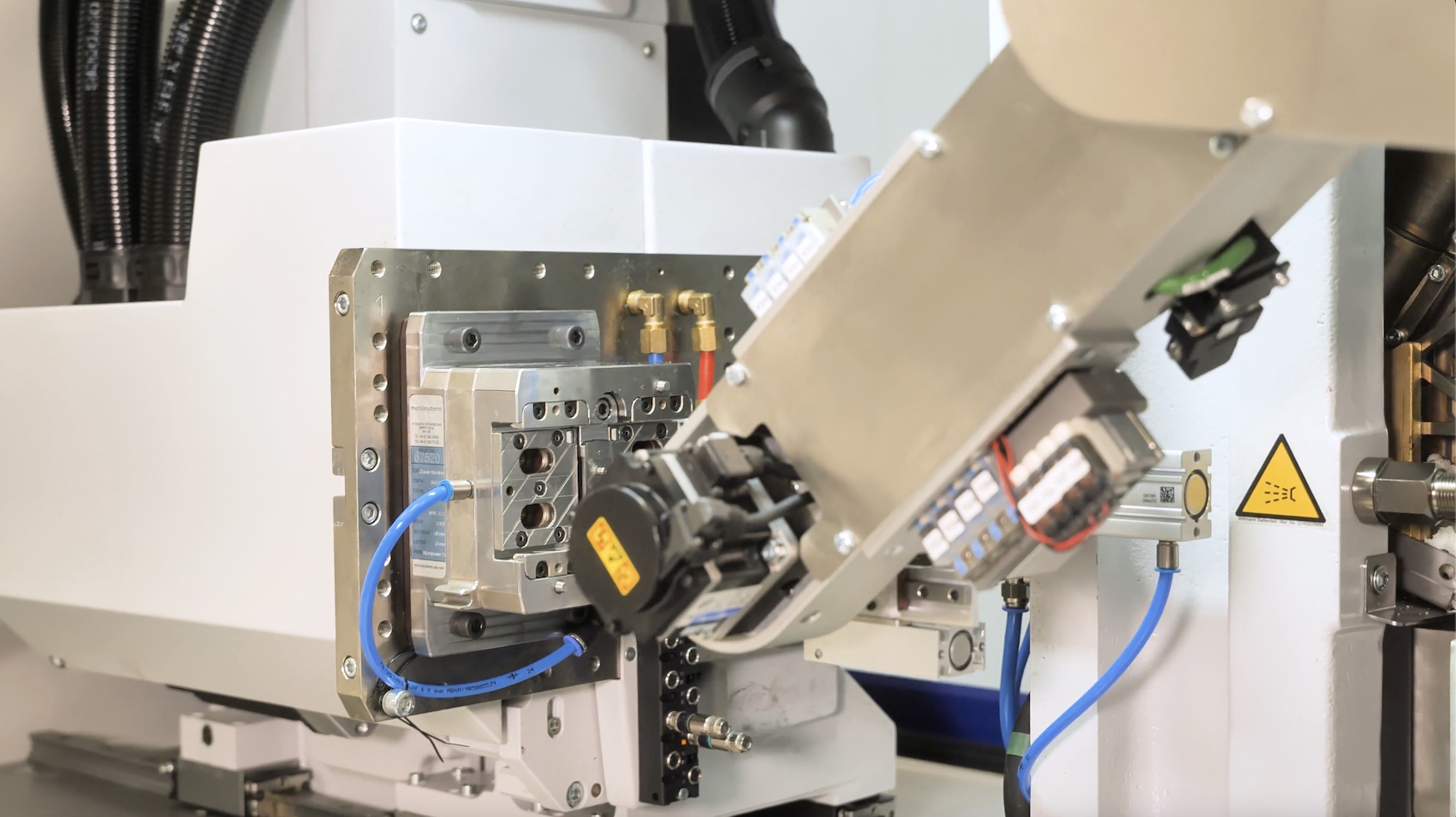

Micro Systems has 20 years of experience in micro mould projects for medical, pharmaceutical and optics markets, from mould design, mould manufacture, micro metrology to plastic injection moulding. All our moulds are manufactured in house and we can utilise diamond cutting techniques which enable us to produce ultra precision micro features with integrated optical areas and surface finishes as low as 5-7 Nm Ra. Our team of experts in the UK and Singapore will work with you from the very first step of your project, to ensure that our moulds meet all of your highest expectations.

- High standards of control – ISO Class 7 Cleanrooms.

- ISO 9001 and ISO 13485

- Pilot moulds to 32 cavity production moulds

- In-house production

- Fast-cycling medical moulds

- Fully validated production moulding

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications, and an ISO Class 7 Cleanroom. For more information, please Contact us or visit our website.