The importance of Prototype Mould

In injection moulding, having Prototype Mould validation could help optimise the final design and shorten tooling manufacture time, ensuring the best outcomes for the moulded products before mass production.

What is Prototype Mould?

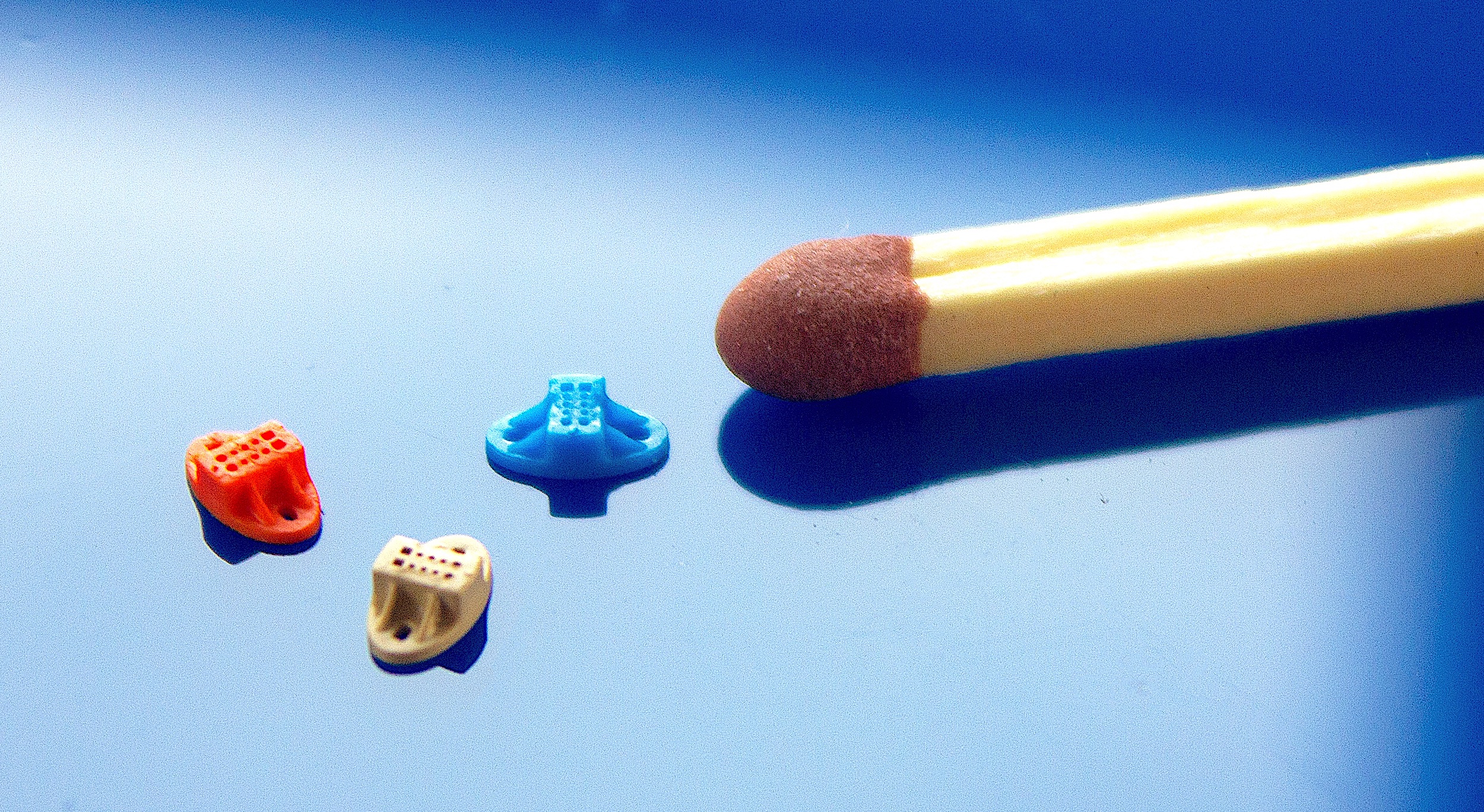

Precise-manufactured prototype moulds can be tested and improved upon prior to going into full-scale manufacturing. This process was created specifically to generate prototypes, short series, and samples rapidly and affordably. Many methods, such as CNC machining and 3D printing can be used for making prototype moulds. Prototype mould should be considered when developing a product in order to expedite the process and lower the possibility of expensive production problems.

Benefits of Prototype Mould

Prototype moulds are crucial to the product development process as they enable faster iterations and more design flexibility in the first phases of the product’s development. This can ultimately lead to more affordable, higher-quality items.

Reduce financial risk

Moulds, especially multi-cavity ones, carry one of the major costs in any injection moulding project, hence, it is important to ensure the mould concept and design work before the final moulds are made. Producing prototype moulds will allow moulders to test their mould concept before finalising the mould design and manufacture to make over a thousand pieces, making it more cost-effective and reasonable. In addition, moulders can also continue using their prototype moulds in the future for small production scale if required.

Supporting proof of concept and Validation

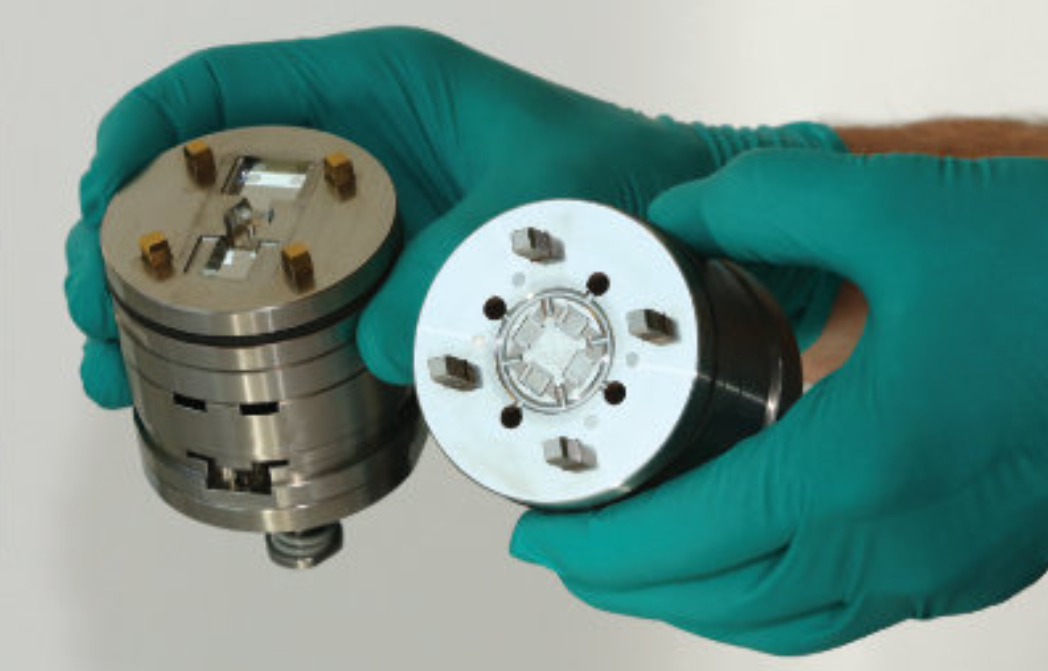

Generally, the manufacture of prototype moulds takes a shorter time than the final moulds, depending on the cavity complexity, meaning moulders can accelerate their process in checking and producing moulded parts. The design, material selection, melt delivery mechanism, surface finishes, plating, venting, and cooling of the pilot mould will all be identical to those of the production mould. Additionally, it will enable the engineering team to build new processes (mouldings) and supply reliable data that will serve as a strong basis for decision-making and validation, two essential steps in the development of high-cavitation production moulds.

Using prototype moulds, moulders can create components that can be put through testing to ensure they work as intended and suit a variety of real-world applications. Early detection of design defects and issues through testing can assist make necessary improvements before large-scale manufacturing starts.

Minimising the concept of risk

Depending on the project, prototype moulds could be made out of aluminium or soft metal alloy, meaning there is more flexibility for adjustments and modifications of cavities, the prototype mould is faster and cheaper to be made, and during the prototyping stage, mould manufacturers can significantly benefit from these flexibilities.

Quickly detecting and resolving any design flaws or possible part problems allows designers and engineers to make modifications to the design prior to mass production. This might lessen the possibility of expensive design errors or flaws that might not be found until the product has started to be produced.

Limitations of Prototype Mould

Cost and time

Even though prototype moulds could help moulders in ensuring their mould design and concept work, it still adds extra cost and time to their injection moulding project. The more cavities there are, the more expensive and the longer the time will take to produce the prototype moulds. Prototype moulds might not be affordable for small projects or projects with limited time and financial budget.

In addition, prototype moulds can only yield a certain number of completed goods before they fully degrade or require replacement. This could be a disadvantage in some circumstances, such when more pieces are needed for testing or assessment.

Limited quality moulded parts

Prototype moulds might not produce components with the same level of accuracy or quality as production moulds. This could be the result of using materials with different specifications or the moulds themselves not having been as precisely calibrated as production moulds. Prototype moulds are more economical to produce smaller quantities of parts than production moulds; but, when larger quantities of parts are needed, the cost per component for prototype moulds could be higher. This is a result of the need for more manpower and the fact that the prototype mould needs to be fixed or replaced more frequently than a production mould does.

For prototype mould validation of certain projects, it is more beneficial for the moulders to go for more advanced tooling techniques in making prototype mould, as prototype moulds produced by quick, lower-cost techniques like 3D printing may not be able to generate products of the highest quality and specification.

Shorter lifespan

As they are composed of less robust materials or because their fine tuning is not as exact as that of production moulds, prototype moulds may have a shorter lifespan than production moulds. This could mean that frequent maintenance or replacements are required, which could affect the cost and production schedule.

With more than 20 years of experience in ultra-precision mould design and mould making, Micro Systems has extensive capabilities in designing, manufacturing and validation prototype moulds, from single to multi cavities. We have on-site our own testing area, along with full-scale injection moulding facilities at Optimold, such that customers can confidently test and validate their prototype moulds.

Contact us today to discuss your prototype mould requirements!