The Medical Injection Moulded Plastics Market

Plastic injection moulding is a cost-effective and efficient method for producing high-precision medical and pharmaceutical products. The market for medical injection-moulded plastics is expected to grow significantly due to rising demand for medical products and ongoing technological advancements.

The market size for Medical Injection Moulded Plastics

According to a recent report, medical injection moulded plastics generated $23,014.7 million in revenue in 2021, and it is anticipated that this amount would increase to $37,899.5 million in 2030 at a pace of 5.7% between 2021 and 2030.

The significant growth in the plastic injection moulding market is driven by increased use in healthcare applications such as implant packaging, mobility aids, and medical devices. Rising R&D spending and technological advancements are boosting demand for medical-grade injection-moulded plastics, offering lighter, smaller, more durable, and cost-effective products. Medical components account for about a quarter of total industry revenue, with this trend expected to continue from 2021 to 2030.

The ageing population and rising prevalence of conditions like cardiovascular and orthopaedic disorders are accelerating demand for implants and mobility aids. North America currently leads the market, accounting for nearly 40% of industry revenue, driven by an ageing population, higher healthcare spending, and favourable regulations. The Asia-Pacific region is expected to grow at over 6%, fuelled by increased use of injection-moulded plastics in medical implants, parts, and assistive devices.

Globally, the plastic injection moulding market was valued at USD 271.6 billion in 2021 and is projected to reach USD 419.1 billion by 2030, growing at a CAGR of 5%. The Asia-Pacific region held 44.8% of the market share in 2021, with North America expected to grow at a CAGR of 5.3% from 2022 to 2030.

Why Injection Moulding for Medical products?

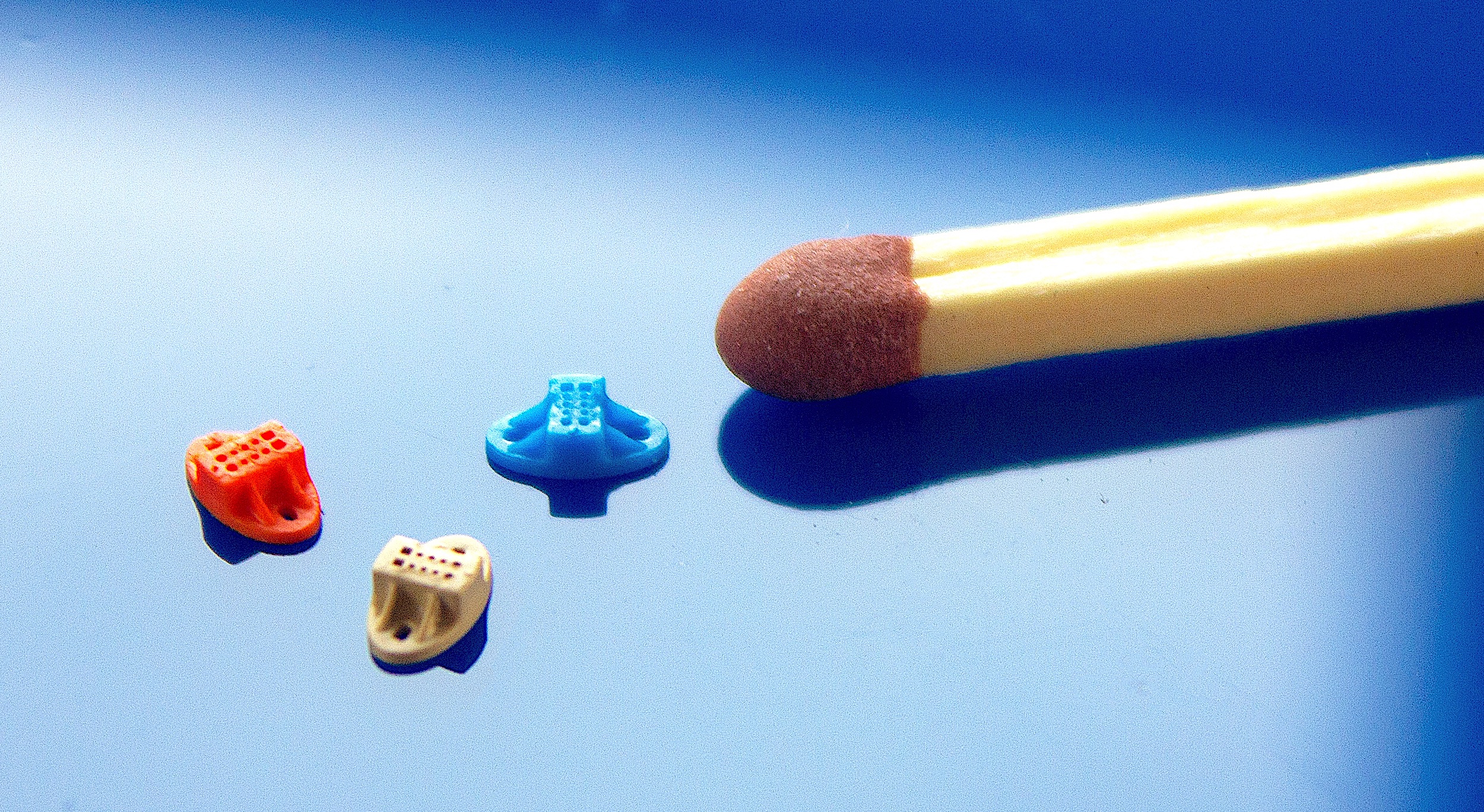

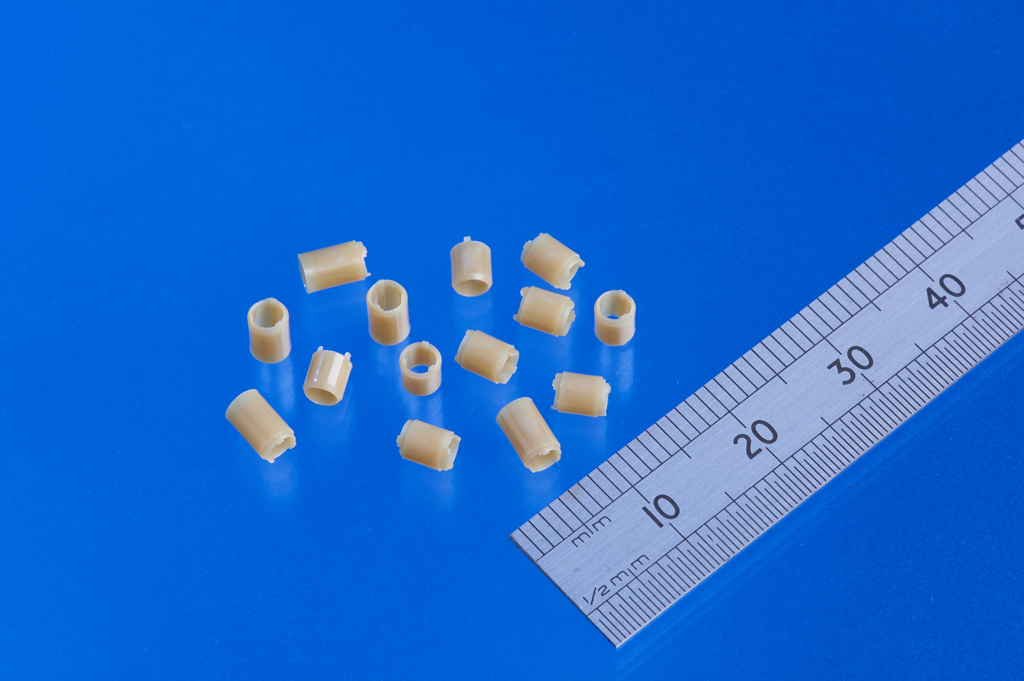

Making medical and pharmaceutical items, such as medical devices, laboratory tools, equipment, and testing instruments, could be more affordable and effective by using the medical injection moulding process. This process produces medical components with a high degree of precision, quality, and accuracy. The chosen Medical-grade plastics are made specifically for use for medical purposes, as it can prevent pharmaceutical contamination and aid in the preservation and containment of medications. For products that need extremely high levels of accuracy and precision, Micro moulding is the ultimate method, as it could achieve final results of a fraction of a millimetre in dimension and tolerance.

Plastic injection moulding for medical and pharmaceutical products and components bring a number of benefits, especially when in the hands of an experienced manufacturer.

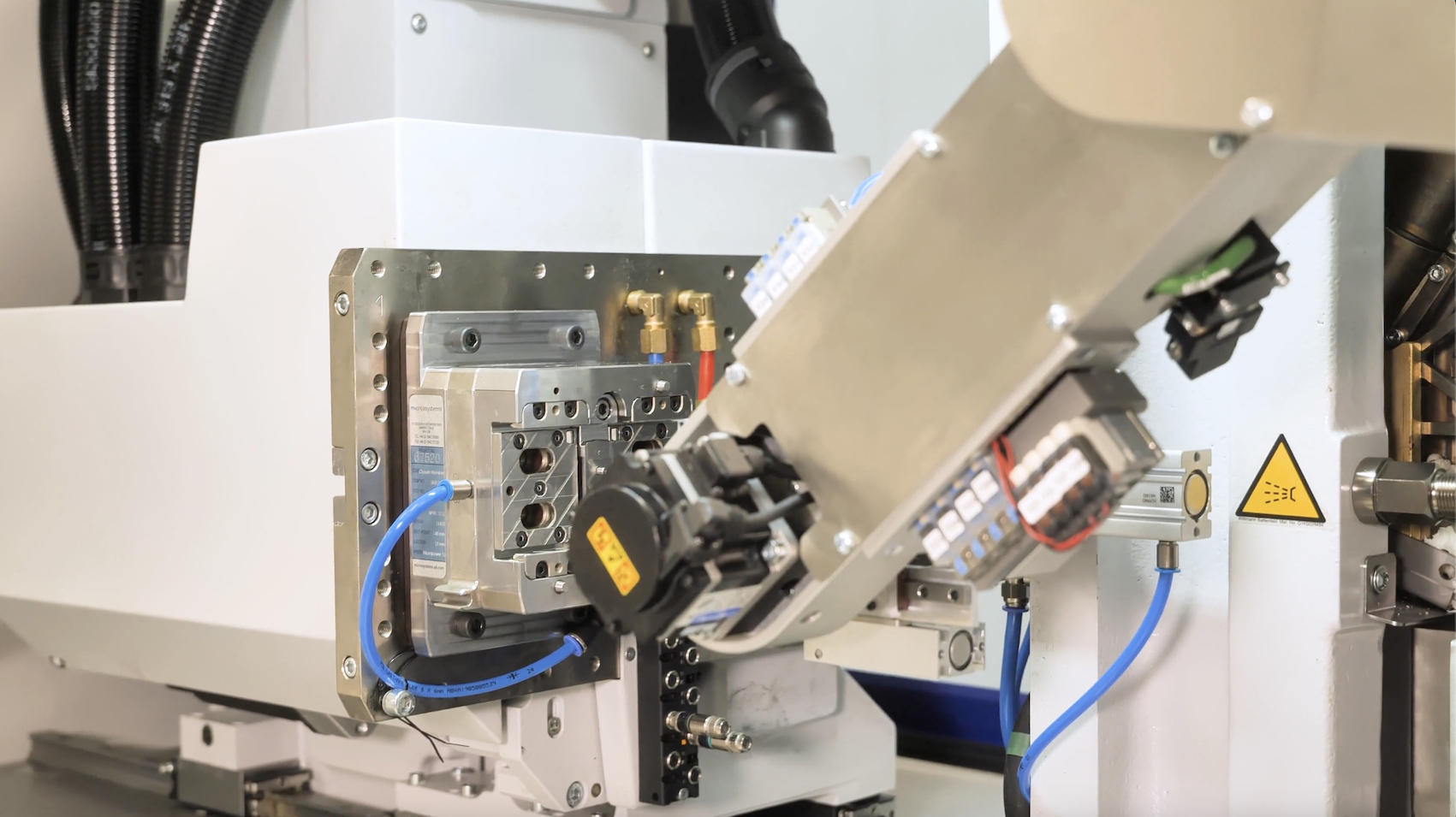

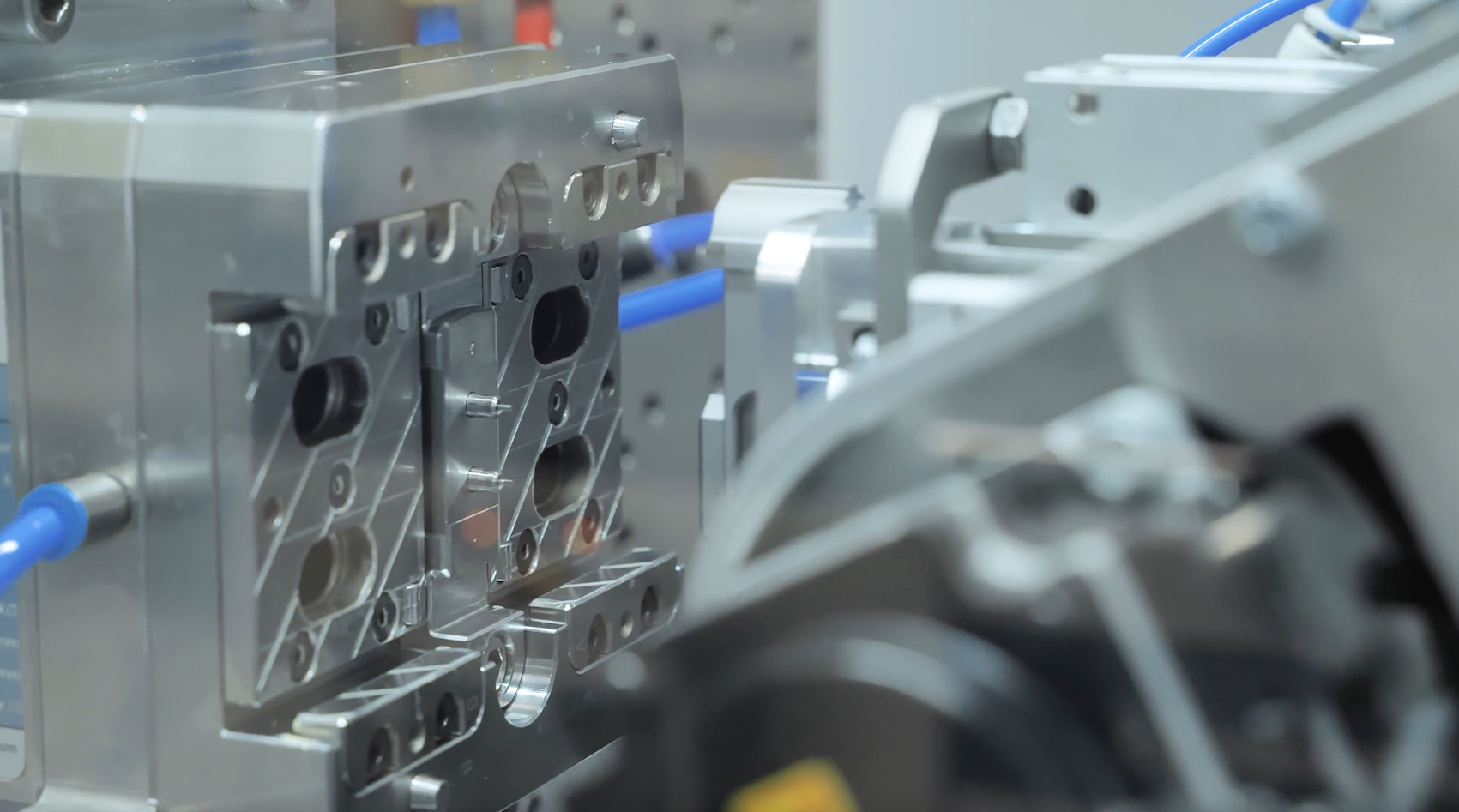

Cost efficiency: Plastic injection moulding is a cost-effective and efficient manufacturing method for high-volume production. Although initial moulding tool costs may be higher, the mould only needs to be created once, lasting for hundreds of thousands of runs before requiring replacement or servicing. As production increases, the cost per unit decreases. With advanced automation in modern injection moulding facilities, the process is faster, requires fewer personnel, and results in higher output with fewer errors.

Durability: The resins used in plastic injection moulding for medical products are durable and resistant to autoclave sterilisation heat. These materials are well-suited for medical applications, as they can withstand vibration, impact, heat, and blunt force without cracking or breaking.

Accuracy: Injection moulding’s precision and reproducibility make it ideal for the medical sector, where even minor errors can result in device failure. By partnering with leading manufacturers like Micro Systems, customers can expect consistent, identical components that meet stringent standards such as ISO 9001 and ISO 13485, ensuring the high precision required in medical device production.

Flexibility: With plastic injection moulding, clients can have the flexibility to go for complex geometries, various colours and materials depending on their preferences. Experienced injection moulding manufacturers have the ability to provide turn-key service, from mould design and manufacture to final part manufacture, so by working with clients from the very first step, they can effectively accommodate each specific design requirement.

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.